Summary: Waking up to factory chaos from surprise failures? It doesn’t have to be this way. Predictive maintenance has promised a lot to manufacturers, yet most implementations stop at dashboards and alerts that rarely change day-to-day decisions. This blog breaks down your pain point and offers solutions and how AI for predictive maintenance in manufacturing is actually used on the shop floor & where AI delivers real value, improving maintenance planning, ROI, and reducing operational firefighting.

If you run a plant, you already know the dirty secret of maintenance. Most equipment breakdowns don’t come from sudden, unpredictable machine failures. Most stoppages are caused by physical degradation inside specific assets such as motors, bearings, pumps, and gearboxes, and this degradation progresses for weeks or months before production halts.

A vibration trend that looked odd but didn’t cross a threshold. A motor running hot but still “within limits.” A gearbox that sounded wrong, yet production had to ship. Traditional maintenance didn’t fail because teams were lazy. Traditional maintenance failed because the tools were blunt.

Did you know that downtime costs $50 billion annually to the manufacturers alone in the US? Can you guess how much the financial impact of downtime on your plant? (Source: Wifitalents)

Predictive maintenance sharpens the edge only when it is built on continuous condition data, accurate failure history, and models that learn how equipment actually degrades in real operating conditions. AI for predictive maintenance in manufacturing is the difference between predictive maintenance that looks good in a PowerPoint and predictive maintenance that actually keeps lines running.

This is where AI in Manufacturing moves from experimentation to execution and where AI for predictive maintenance in manufacturing stops being a buzzword and starts being a commercial lever.

Why predictive maintenance still fails in many factories?

Predictive maintenance fails because most systems still rely on rigid rules that generate noise instead of insight, leading teams to stop trusting alerts.

Without real pattern learning, operational integration, and AI for predictive maintenance in the manufacturing industry, initiatives stall at pilots and fail to deliver value.

Let’s get uncomfortable for a moment. Most “predictive maintenance” setups today are rule-based systems wearing a new label. Fixed thresholds. Simple trend lines. If X crosses Y, raise an alert.

That approach worked when assets were simpler, and data volumes were small. Predictive maintenance built on fixed thresholds may look reliable, but it struggles in today’s complex manufacturing environments.

Here’s what we see on the ground:

- Too many alerts, not enough insight

- Maintenance teams ignore alarms because 8 out of 10 are false.

- AI pilots that never scale beyond one line or one asset type

- OEM black boxes that don’t fit how the plant actually operates

The core issue isn’t sensors or connectivity, it’s interpretation. Machines don’t fail linearly; they drift and interact. Machines degrade differently depending on load, operator behavior, and upstream variability.

This is also where many teams go wrong by treating predictive maintenance as a tool rollout instead of a system design problem, something any practical AI app development guide warns about early. Without the right data pipelines, feedback loops, and operational integration, even good models fail to deliver value. That’s the gap AI fills, by learning patterns humans can’t reliably see.

What is the real role of AI in predictive maintenance?

AI’s real role in predictive maintenance is to reduce noise, surface risk earlier, and give maintenance teams time to act with confidence. When AI for predictive maintenance in manufacturing gives teams days to plan instead of hours to react, the system delivers control, not just predictions.

Let’s be clear about priorities: the role of AI in predictive maintenance is not to replace maintenance engineers. It’s to remove noise, compress decision time, and surface risk earlier with higher confidence.

Anything beyond that is secondary. AI earns its place when AI does three things better than traditional systems:

- Learns normal behavior, not just failure thresholds

- Adapts as machines age and operating conditions change.

- Connects weak signals across multiple data sources

This matters more than fancy dashboards or “self-healing” marketing claims. In manufacturing, time is money. But certainty is worth more. If an AI model can give a maintenance lead a 10-day warning window instead of a 2-hour scramble, that’s not an incremental improvement. That’s schedule control.

How AI Improves Predictive Maintenance in Manufacturing?

Forget the textbook diagrams for a minute. Here’s the practical version engineers end up dealing with after the pilot phase.

AI for predictive maintenance in manufacturing usually follows this flow, but the real value comes from what happens inside each step, not the step itself.

Data ingestion (where most problems quietly start)

Yes, you collect sensor data. Vibration, temperature, acoustics, current, pressure. Sometimes oil analysis, sometimes vision data. On top of that, operational context from PLCs, SCADA, MES, and quality systems.

What matters here isn’t volume. It’s alignment. Raw sensor data without an operating context is nearly useless. A motor pulling high current during ramp-up is normal. The same current during steady-state is not. AI for predictive maintenance in the manufacturing industry relies on this context to distinguish normal operational variance from early signs of degradation.

AI systems need timestamps synced across sources, consistent sampling rates, and clear tagging of operating modes. This is where many maintenance teams stumble. The teams ingest all available sensor and operational data, normalize nothing, and call the raw, unprocessed setup “connected manufacturing.” Good systems explicitly segment data by operating state: startup, steady load, transient, idle. Without that, the model learns noise and confidently reports nonsense.

Feature learning (where AI earns its paycheck)

AI models don’t work on raw sensor streams for long. They convert signals into features that capture how a machine behaves over time.

In vibration analysis, that might mean frequency-domain features like spectral energy bands, kurtosis, crest factor, or sideband amplitudes. In electrical systems, the AI model could extract features such as current imbalance, harmonic distortion, or phase shift patterns. In thermal data, the model often focuses on the rate of change rather than absolute temperature. The key point is that these extracted features evolve over time and are not static.

AI for predictive maintenance in manufacturing continuously relearns what “normal” looks like as machines age, loads shift, or upstream processes change. Traditional condition monitoring systems treat the baseline as fixed. AI treats baseline as moving.

That’s the real difference. Not intelligence but adaptability. This is also why model training takes time. You’re not teaching the system what failure looks like. You’re teaching it what healthy variability looks like, so degradation stands out.

Anomaly detection (precision beats sensitivity)

This is where most marketing claims live, and most operational frustration happens. Threshold-based systems ask a simple question: Did a value cross a predefined limit?

AI for predictive maintenance in manufacturing asks a harder one: Does this pattern deviate from expected behavior given the current operating context and historical behavior of this specific asset?

Practically, this means using techniques like multivariate anomaly detection, time-series forecasting error analysis, or similarity scoring against learned healthy states. The goal isn’t to detect everything. It’s to detect meaningful deviations early, without flooding teams with alerts.

False positives kill trust faster than missed failures. Experienced plants tune models to favor precision over sensitivity, especially in the first rollout phase. This alone can cut inspection hours significantly, because teams stop chasing ghosts.

Failure mode correlation (the step that separates toys from tools)

Detecting an anomaly is easy, whereas, explaining is hard. Advanced systems correlate anomalies across multiple signals to infer likely failure modes. For example, a specific vibration frequency combined with rising motor current and localized heating points to bearing degradation, not misalignment.

Correlating anomalies can be rule-assisted, model-assisted, or hybrid. Pure AI is rarely enough, and domain knowledge still matters. The failure mode correlation step is critical because maintenance actions are expensive. Pulling the wrong component early doesn’t just waste parts; it can cause unnecessary downtime that could have been avoided.

Systems that stop at “something is wrong” force humans to do the hardest part under time pressure. That’s where mistakes happen.

Remaining Useful Life estimation (where expectations need to be managed)

RUL predictions often get oversold. Let’s be honest: in real manufacturing environments, AI for predictive maintenance does not predict an exact failure date. Instead, AI estimates degradation trajectories with confidence intervals.

Estimating these degradation trajectories is still valuable because knowing there is a 7–14 day window, instead of “the machine might fail tomorrow,” changes how maintenance is planned. This estimation allows maintenance teams to align work with production schedules, spare parts availability, and labor shifts.

The common mistake is treating RUL predictions as exact promises rather than planning inputs. When used correctly, these predictions reduce chaos; when used blindly, relying on them as guarantees creates false confidence.

Decision support (where most systems quietly fail)

This is where many solutions fall apart. Alerts without context don’t help. Neither do probability scores without recommended actions.

Effective AI for predictive maintenance in manufacturing translates technical insight into operational decisions:

– Keep running and monitoring

– Inspect at the next planned stop

– Schedule replacement within a defined window

– Shut down immediately

These recommendations are usually confidence-weighted and linked to past outcomes. Over time, the system learns which actions actually prevented failures and which didn’t. If your predictive maintenance platform can’t close that feedback loop, it stays academic.

That’s the practical answer to how AI in predictive maintenance works for manufacturing. It’s disciplined signal processing, adaptive models, and decision logic built around how factories actually operate. And that discipline matters far more than whatever algorithm name is on the slide deck.

Why AI-based predictive maintenance matters commercially?

AI-based predictive maintenance matters commercially because unplanned downtime destroys margins faster than almost any other operational issue.

When failures are predicted early, teams protect throughput, avoid emergency costs, and keep delivery commitments intact.

When a line goes down unexpectedly, you don’t just lose production. You pay overtime, miss delivery windows, stress upstream and downstream operations, and sometimes damage customer trust.

AI changes the economics in three ways.

1. Fewer surprise failures

Even a modest reduction in unplanned downtime moves the needle. In asset-heavy plants, a single avoided failure can justify months of model training costs.

2. Better maintenance timing

Replacing components too early is expensive. Replacing them too late is worse.

AI narrows that window. This matters more than most people admit.

3. Labor efficiency

Skilled maintenance talent is scarce, and AI for predictive maintenance does not replace these experts. Instead, AI enhances their judgment, allowing maintenance teams to focus on the decisions that matter most.

This is why CEOs should care, not just plant managers. Predictive maintenance powered by AI isn’t a technical upgrade. It’s a risk management tool.

Where AI delivers the most value and where it doesn’t?

Here’s an opinion that might ruffle feathers: AI for predictive maintenance delivers the most value in complex, variable, and high-cost assets. The same AI provides far less benefit when applied to simple, inexpensive, or easily replaceable equipment.

If a pump costs $200 and takes 20 minutes to replace, don’t overthink it. If a robot arm failure halts an entire line and takes two days to recalibrate, that’s where AI belongs.

Prioritization matters. We’ve seen plants burn budget by rolling out AI everywhere instead of focusing on the 20 percent of assets that cause 80 percent of disruption. That’s not an AI problem. That’s a leadership problem.

AI transforms predictive maintenance in the manufacturing industry by scaling judgment.

There’s a subtle but important shift happening. Traditional maintenance relied on experience. The best technicians could hear, feel, or sense issues before systems flagged them.

That approach does not scale. AI for predictive maintenance captures fragments of the experiential judgment and intuition of the best maintenance technicians and applies that insight across thousands of machines, shifts, and conditions. While the application is not perfect, it is consistent, and in manufacturing operations, consistency beats brilliance.

Capturing and scaling this human insight is where AI truly transforms predictive maintenance in the industry. AI for predictive maintenance allows good judgment to scale across the plant without overworking or burning out your most skilled maintenance staff.

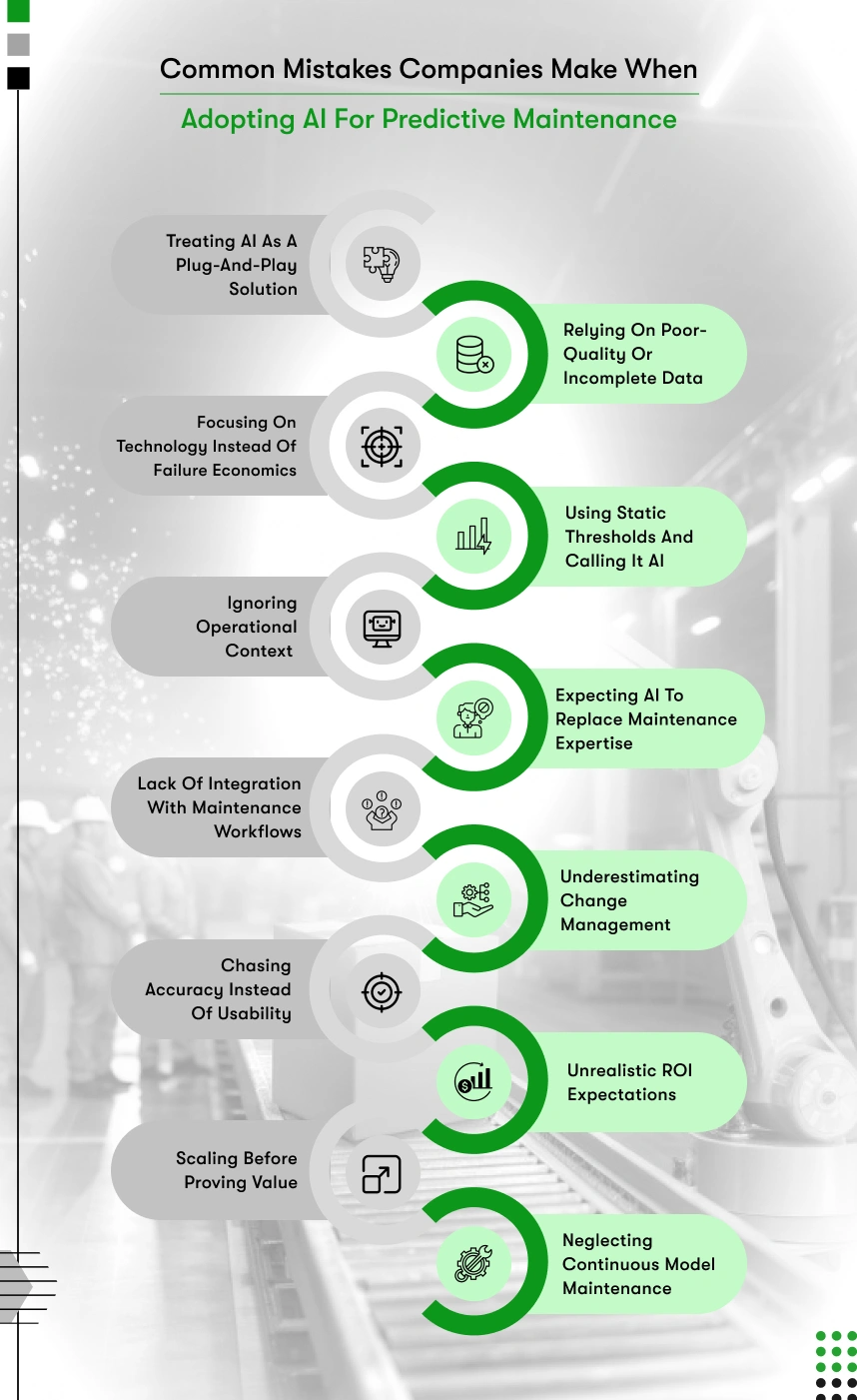

Common mistakes companies make when adopting AI for predictive maintenance in the maintenance Industry

Let’s save you some pain. Starting with technology instead of failure economics

If you can’t quantify the cost of failure, you can’t justify the model.

Expecting instant accuracy

AI models need time. If leadership panics after three months, the project dies.

Ignoring integration

Predictive insights that don’t connect to CMMS workflows are just interesting charts.

Letting vendors hide the logic

Black boxes are tempting. They’re also dangerous.

If your team doesn’t understand why a recommendation was made, they won’t trust it. This is why experienced partners matter more than flashy demos. It’s also where strong AI Development Services make a real difference.

What are the benefits of AI in predictive maintenance in manufacturing?

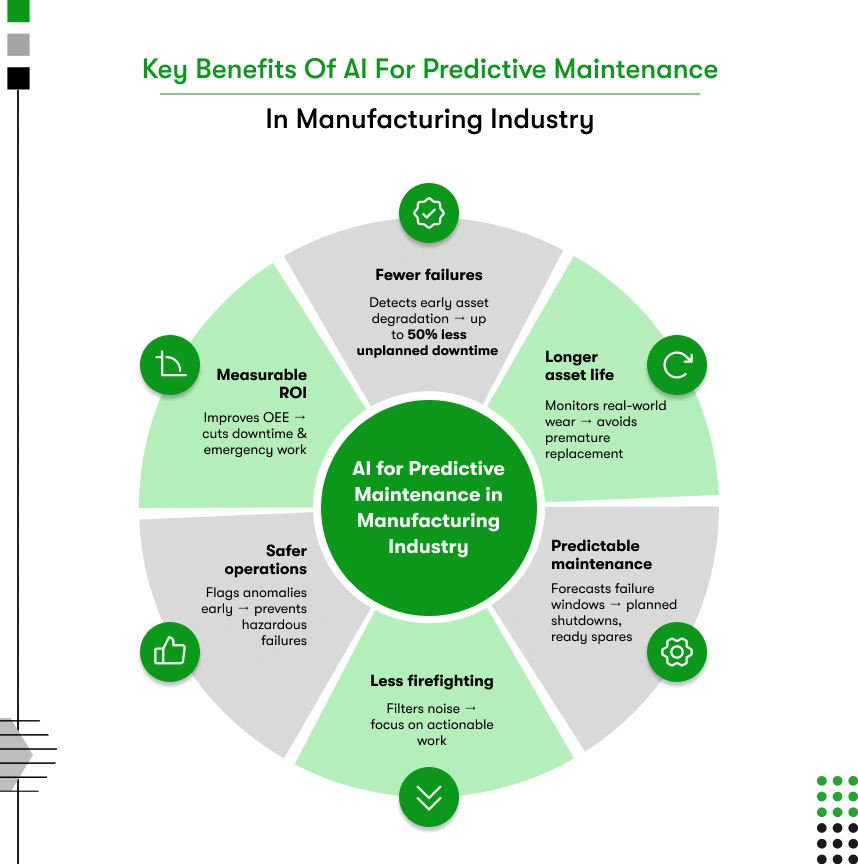

Let’s cut through the generic lists. The real benefits of AI for Predictive Maintenance in Manufacturing show up only when they reduce failure, stabilize planning, and take pressure off people. Everything else is secondary.

Fewer catastrophic failures where it hurts most

AI for predictive maintenance does not attempt to predict every possible failure. Instead, the AI focuses on detecting early signs of degradation in high-impact assets. Focusing on early risk identification in critical equipment is the practical role of AI in predictive maintenance, because it targets issues where unplanned downtime is most costly.

That’s why plants that deploy AI for predictive maintenance in manufacturing properly often see up to 50% reduction in unplanned downtime on critical lines. Preventing one line-stopping failure can pay for the system on its own.

Longer asset life, without gambling on averages

Traditional maintenance relies on calendar intervals and generic OEM guidelines. AI transforms predictive maintenance in the manufacturing industry by tracking how each asset actually degrades under real operating conditions.

Instead of averages, decisions are based on real behavior. The result is fewer premature replacements and fewer run-to-failure events. Asset life increases where replacement and recalibration costs are highest.

Maintenance planning that production can trust

When AI provides realistic failure windows instead of last-minute alarms, maintenance becomes schedulable. This is one of the most tangible benefits of AI in predictive maintenance in manufacturing.

Shutdowns align with production cycles. Spare parts planning improves. Emergency procurement drops. This is where predictive maintenance stops being reactive support and starts influencing plant-level planning.

Reduced firefighting and decision pressure

One of the highest hidden costs in manufacturing is constant reaction. AI for Predictive Maintenance in the Manufacturing Industry reduces false alarms and surfaces only actionable issues.

That means fewer rushed inspections, fewer late-night calls, and fewer decisions made under stress. Teams spend more time executing planned work and less time chasing symptoms.

Safer operations through early fault isolation

Late-stage mechanical failures are often safety incidents waiting to happen. AI flags abnormal behavior before conditions become hazardous.

This highlights how AI in predictive maintenance works for manufacturing by isolating faults early enough to prevent emergency interventions and reduce exposure risks for maintenance teams. Safety improves as a result of earlier insight, not extra compliance effort.

Real ROI that shows up in operational metrics

These benefits don’t live in strategy decks. They show up in OEE improvement, lower spare-parts inventory buffers, fewer weekend call-outs, and measurable downtime reduction.

This is why AI for Predictive Maintenance in the Manufacturing Industry is often the first serious AI use case manufacturers scale.

This is also where AI transforms predictive maintenance in the manufacturing industry in a way leadership actually cares about, not by being smarter, but by being earlier, calmer, and more consistent than human-only systems can be.

AI-powered predictive maintenance fits naturally alongside broader AI-driven automation efforts and reinforces measurable benefits from AI in manufacturing. Predictive maintenance using AI aligns with proven AI manufacturing trends because it addresses operational risk directly rather than indirectly.

The principle is simple: if AI in predictive maintenance fails to reduce chaos, improve planning confidence, or protect production throughput, it is not fulfilling its purpose. Similarly, if the effectiveness of AI cannot be measured in terms of downtime avoided and failures prevented, that AI solution does not belong in a production environment.

How does this tie into the broader manufacturing AI strategy?

AI-powered predictive maintenance connects directly to other AI use cases in manufacturing, including robotics, uptime optimization, quality control, and production planning. By integrating predictive maintenance with these areas, manufacturers can create a more cohesive AI ecosystem that maximizes operational efficiency and reduces unplanned downtime across the plant.

This type of predictive maintenance also intersects with AI in automation, especially in lights-out or semi-autonomous environments where early detection of failures is more difficult. By providing early warnings and actionable insights, AI-powered predictive maintenance helps automated systems avoid costly disruptions and maintain consistent throughput, even when human oversight is limited.

Additionally, AI-powered predictive maintenance contributes to broader AI benefits in manufacturing, such as improved decision-making, risk reduction, and operational visibility. The measurable early ROI and tangible impact on maintenance operations are why many manufacturers prioritize predictive maintenance before expanding AI applications into planning, scheduling, or process optimization. Starting with predictive maintenance allows plants to see real value quickly and build confidence for scaling AI more broadly.

Data quality beats model sophistication every time.

Here’s a hard truth. A mediocre model trained on good data beats a brilliant model trained on garbage. We’ve seen teams chase exotic algorithms while ignoring sensor calibration, data gaps, or inconsistent labeling.

AI in predictive maintenance is not forgiving; it amplifies the quality and accuracy of the data and instructions it receives. Because of this amplification effect, experienced engineering and careful system design matter far more than flashy marketing or hype. The amplification effect of AI is also the reason why teams exploring AI trends in manufacturing need to clearly separate approaches that are merely fashionable from solutions that are truly feasible and operationally effective.

The human factor doesn’t disappear.

One more uncomfortable point is that AI in predictive maintenance does not eliminate human bias; instead, it changes where bias appears in decision-making. If machine operators do not trust the AI-generated alerts, they may ignore them. Likewise, if maintenance teams are not engaged early in the process, they may resist following the AI-driven recommendations.

Successful deployments treat AI as a colleague, not an oracle. That requires change management. Training. Feedback loops. No model fixes organizational blind spots on its own.

Predictive maintenance and the supply chain connection

This part is often overlooked. Better failure prediction improves spare parts planning. That links directly to AI for supply chain efficiency. Knowing which components are likely to fail and when reduces emergency procurement, excess inventory, and supplier pressure.

This matters more in global manufacturing environments where lead times are long and volatility is real.

How to Choose the right approach to AI development

Off-the-shelf tools can work. Custom platforms can work too. The decision depends on asset complexity, data maturity, and how much differentiation maintenance performance creates for your business.

Some manufacturers need quick wins. Others need deep integration. That’s where options like Hire AI Developers or following a structured AI app development guide come into play, not as checkboxes, but as strategic choices.

There’s no universal answer. Anyone who says otherwise hasn’t done this at scale.

Why predictive maintenance is a CEO and COO problem, not just an engineering one?

Maintenance failures show uFp on financial statements, not just dashboards. They hit revenue, margins, and customer confidence.

When leadership treats predictive maintenance as a technical experiment instead of an operational discipline, it stays stuck in pilot mode.

AI in manufacturing only delivers value when ownership is clear, and incentives are aligned. That’s not a software issue. That’s governance.

This is the perfect time to adapt to AI for predictive maintenance in your manufacturing industry.

AI for predictive maintenance in the manufacturing industry isn’t about chasing the future. It’s about removing avoidable chaos from operations today.

The manufacturing plants that achieve the best results aren’t the ones with the fanciest AI models. The most successful plants are those that apply AI-powered predictive maintenance to the equipment where failures have the highest impact and integrate these AI insights directly into operational decision-making.

If you’re exploring predictive maintenance seriously and want to cut through the noise, start with your failure economics. Then your data. Then your people. The technology will follow.

At Kody Technolab Ltd., we work with heavy plants, process manufacturers, and asset-intensive operations to identify where decisions break down and apply AI for predictive maintenance in the manufacturing industry in a way that fits real operations, not demo environments.

If you’re looking for a grounded discussion on how this applies to your plant and want to see it in action, contact Kody Technolab Ltd. for a practical conversation and demo.

FAQ

1. Is AI for predictive maintenance suitable for every manufacturing facility?

Not always, and that’s an important distinction. AI delivers the most value in asset-heavy, highly automated environments where unexpected failures lead to real downtime and production losses. Discrete manufacturing plants, robotics-driven lines, and continuous process operations tend to see far greater benefits than facilities that rely on low-cost or easily replaceable equipment.

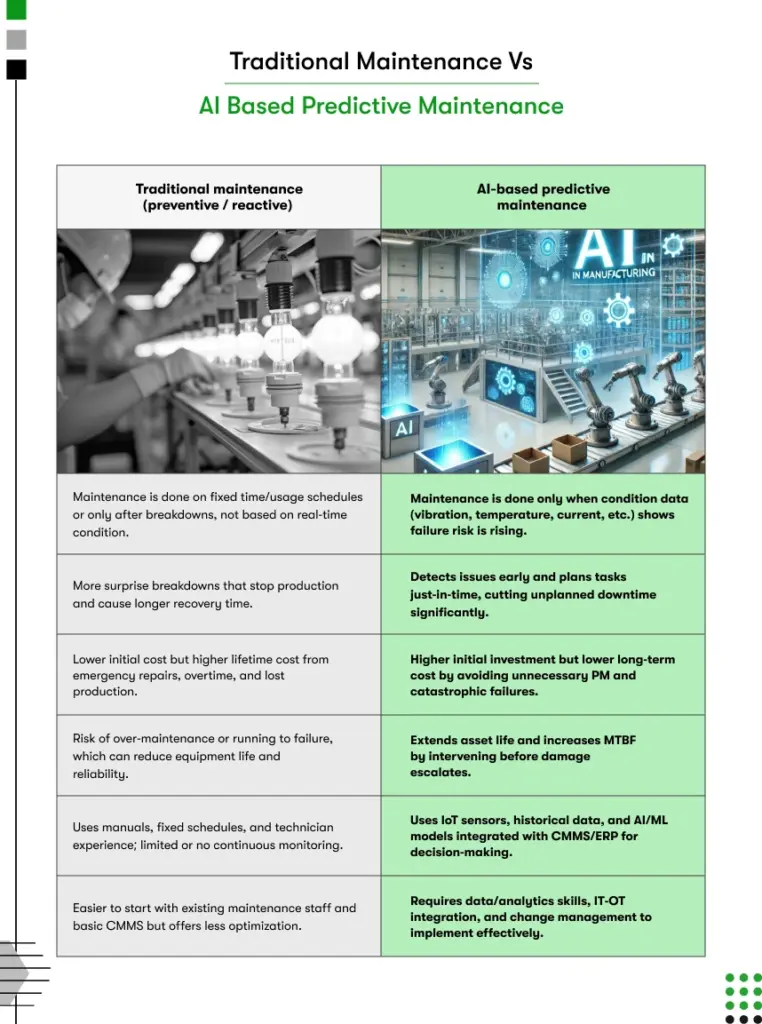

2. How is AI-based predictive maintenance different from traditional condition monitoring?

Traditional condition monitoring depends on fixed thresholds and predefined rules. AI takes a different approach. It learns how each machine behaves across different loads, ages, and operating conditions. This allows it to spot early signs of degradation that static rules often miss while also reducing false alarms in complex manufacturing environments.

3. What type of data is needed to implement AI in predictive maintenance?

Sensor data alone rarely tells the full story. AI performs best when vibration, temperature, current, and pressure data are combined with operational context from PLCs, SCADA, and MES systems. In practice, data quality, consistency, and proper tagging by operating state matter far more than collecting massive volumes of raw signals.

4. How long does it typically take to see ROI from AI for predictive maintenance in manufacturing?

Most manufacturers begin to see measurable results within 6 to 12 months, depending on asset criticality and data readiness. The real ROI usually comes from fewer unplanned shutdowns, better maintenance scheduling, and a reduction in emergency repairs, not from predicting every possible failure scenario.

5. Can AI in predictive maintenance replace maintenance engineers or technicians?

No, and it isn’t meant to. AI’s role is to support better decision-making, not replace human expertise. By reducing noise and highlighting risk earlier, AI allows maintenance teams to focus on high-value work instead of constantly reacting to breakdowns.

6. Why do many AI predictive maintenance initiatives fail?

The most common issues are poor data quality, expectations of instant accuracy, and weak integration with existing maintenance workflows. AI transforms predictive maintenance in manufacturing only when it’s connected to real failure costs and embedded into everyday operational decisions, not treated as a standalone analytics project.

Contact Information

Contact Information