Quick Summary: Supply chain disruption drains margin because decisions arrive too late. This guide shows how AI in the supply chain creates earlier warnings, accurate actions and measurable cost and carbon gains across real workflows. Leaders learn practical steps to launch AI programs with confidence and turn unstable operations into predictable performance.

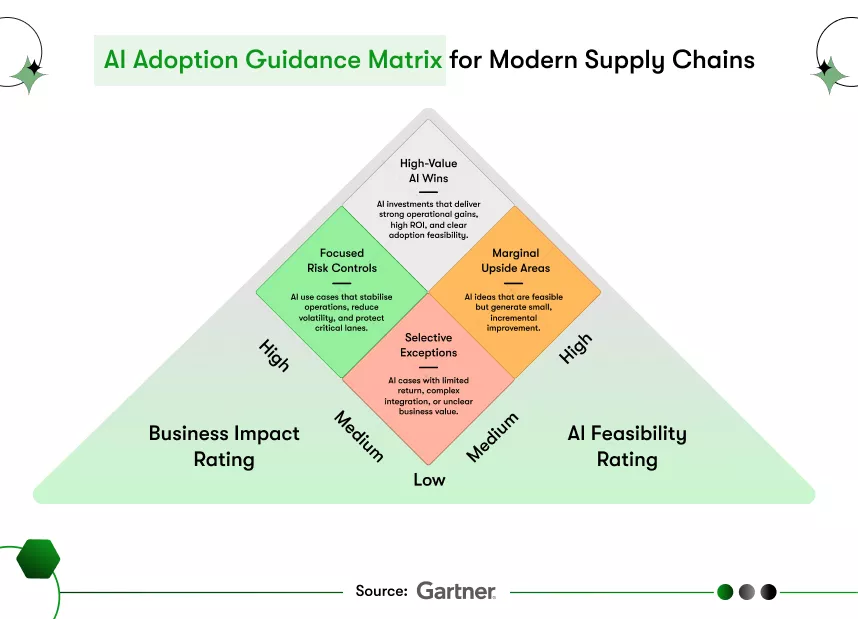

You watch a port closure wipe out tomorrow’s delivery and the entire plan built around it. (Source: Gartner) reports that 95 percent of data-driven decisions will be partly automated next year, yet only 10 percent of CEOs use AI in supply chain management with a defined strategy. Artificial intelligence supply chain systems prevent these disruptions by scanning purchase orders, port feeds and weather alerts to push a reroute plan days before the impact hits.

In the next three minutes, you will see how generative AI in supply chain operations creates alternate lanes in minutes, reduces stockouts and removes expensive emergency air freight. You will also review AI in supply chain examples that show measurable financial gains and understand how AI improves sustainability in supply chain performance.

Use the five-step checklist to launch AI in logistics and supply chain this quarter without hiring a data scientist, and convert chaos into predictable, reliable margin.

If you plan to build a manufacturing app and want a clear starting point, explore our AI in Manufacturing Guide for practical steps, examples, and a complete roadmap.

Why AI in Supply Chain Is Now a Strategic Advantage

Your supply chain plans collapse when a single missed sailing wipes out days of preparation and pushes freight costs beyond the budget. Spreadsheets and legacy dashboards show yesterday’s status, which leaves supply chain teams reacting after the damage hits the margin. AI in supply chain operations closes this blind spot through early signals that alert planners before a disruption reaches inventory, production or fulfillment.

The Real Cost of Manual Firefighting

Stockouts trigger costly emergency air freight. A supplier delay disrupts six-week production plans. A missed route pushes delivery past the retail commitment and invites penalties.

Each disruption reduces margin, slows cash rotation and weakens customer confidence.

Planners manage alerts the moment the issue becomes visible, but those alerts appear after the financial impact has already started because traditional systems do not evaluate forward-looking events.

The Gartner Reality: The 25% KPI Automation Shift

Gartner projects that 25 percent of KPI reporting will be generated through GenAI models. Automated visibility brings faster trend recognition, stronger risk signals and cleaner operational reporting. This level of automation helps leaders act earlier, adjust before constraints harden and build stability that manual reporting struggles to support.

AI in supply chain and artificial intelligence supply chain systems improve visibility, strengthen planning accuracy and support continuity across global operations, especially as AI in automation quietly upgrades every core workflow behind the scenes.

You just watched a typhoon idle the port and erase your delivery promise. The fix is not another emergency Zoom call; it is a six step loop that turns your existing PO, ASN and TMS files into an early warning system. Later in this post you will see the exact template, a free Google Sheet plus a seven minute walkthrough, that planners use to flag which containers to reroute, which suppliers to buffer, and how much cash they can save before the next storm is even named. First, here is how the loop works inside a live supply chain.

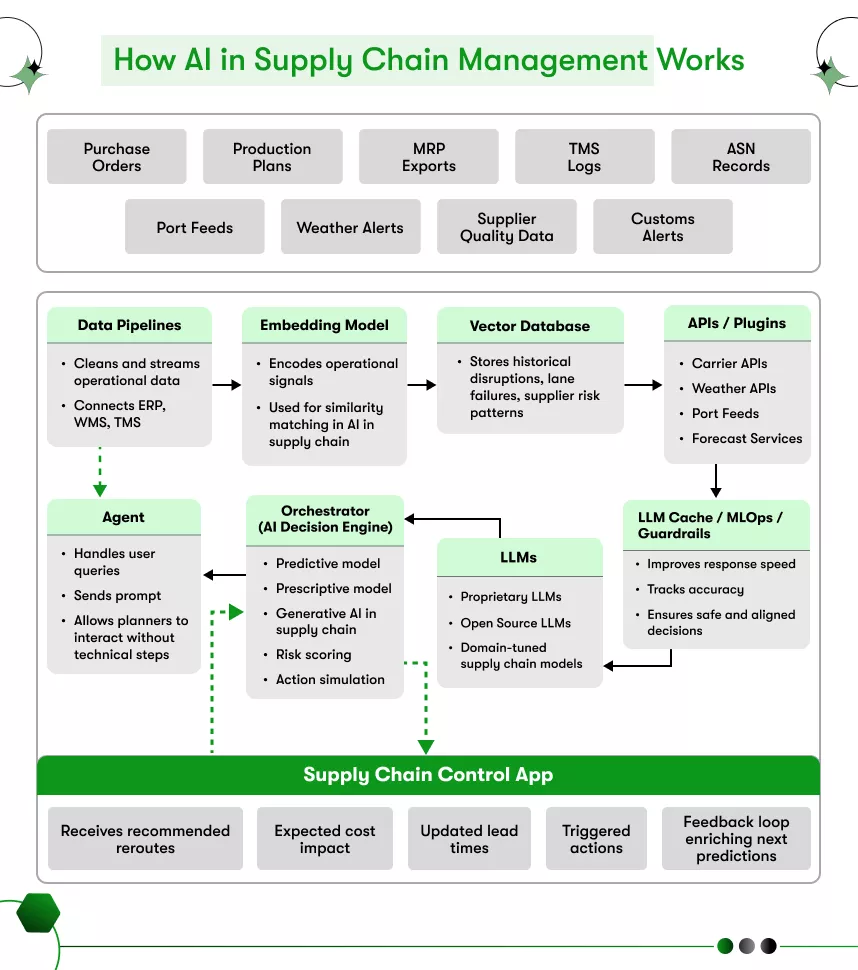

How AI in Supply Chain Management Works (No Code Needed)

Most teams think AI requires a large engineering setup. You do not need that. AI in supply chain for manufacturing works when your existing data connects to models trained to predict risk, recommend decisions and automate repetitive actions. The impact comes from the way the system reads your daily operations, not from technical complexity.

This explanation breaks down the internal flow in a way CEOs, CTOs and operations leaders rely on when evaluating enterprise investments in AI in the supply chain. The goal is to show how the technology works in real operations without complexity or technical confusion.

Data You Already Own (and Never Fully Use)

Generative AI in the supply chain does not start with new tools. It starts with the scattered data your teams already generate every day. You can activate AI in supply chain for manufacturing using four core data blocks:

A. Purchase and production data

Purchase orders, production plans and MRP exports show what you plan to build, when material should arrive and which lines depend on it. A generative AI in supply chain model learns your upstream pressure points and predicts where the next shortage is likely to hit.

B. Logistics and routing data

TMS logs capture transit times, delays, rolled bookings, equipment shortages and seasonal congestion. AI in the supply chain reads this history and builds a live expectation of which lanes, carriers or routes are most likely to fail before they disrupt your schedule.

C. Supplier performance data

Late ASNs, quality claims and defect reports all act as risk markers. A generative AI in a supply chain engine uses this record to calculate the probability of a supplier slipping weeks before your planners spot the pattern in dashboards.

D. External signals

Port feeds, customs alerts, weather services and news streams form the outside signal layer. AI blends these external signals with your internal data so you see likely disruptions early instead of reacting after containers stop moving.

Outcome: You build a single intelligence layer from data you already own. AI in supply chain management runs on top of your existing systems, so your team can start without custom code or a new technology stack, while still getting enterprise-level foresight.

Predictive, Prescriptive and Generative Models Working Together

AI in supply chain management does not depend on a single clever algorithm. You get real value when three model types work in sequence on your own operational data.

1. Predictive models

Predictive models analyse your historical orders, shipments, lead times and disruption events to forecast:

- when demand is likely to spike

- when a supplier is likely to miss a promise

- when a route has high risk of failure

- when inventory will fall below safe levels

In simple terms, predictive models estimate what will happen next so you are not surprised.

2. Prescriptive models

Prescriptive models turn those predictions into specific actions you can take. They recommend:

- alternate lanes that still meet service targets

- carriers that have capacity and reliable performance

- quantity and mix adjustments across SKUs

- reallocation of inventory across regions or channels

- revised production schedules that protect priority orders

Prescriptive models answer a clearer question: given the forecast, what should you do now.

3. Generative models

Generative AI in the supply chain adds a third layer that designs new options you would not plan manually. These models:

- simulate thousands of route and mode combinations

- test different supplier mixes and MOQ scenarios

- explore alternative build schedules and staging points

- search for plans that reduce cost while protecting service

Generative models expand the option set and highlight the plans that protect margin, improve resilience and reduce risk. When predictive, prescriptive and generative models run together, AI in the supply chain absorbs pattern-based intelligence seen across AI in manufacturing examples and turns raw data into concrete decisions you can execute with confidence.

What Happens Inside the System When You Start Using AI in Supply Chain

AI in the supply chain for manufacturing works behind the scenes in a continuous loop that reads your operations, predicts trouble early and guides your team with clear recommended actions. The process moves from risk detection to decision support without forcing you to change your existing platforms.

Each layer strengthens planning accuracy and reduces expensive surprises across lanes, suppliers and customers. Leaders trust this flow because every step produces measurable business value.

Step 1: The system reads your operations in real time

AI in supply chain management connects to ERP, WMS and TMS feeds.

The engine processes every new order, status update and movement without waiting for batch reports.

You receive timely signals because the model watches your network continuously.

The system monitors:

- live purchase order updates

- carrier schedule shifts

- inventory movements across nodes

- lane performance changes

Step 2: The model identifies early signs of disruption

The engine compares your live data with historical patterns to highlight unusual behaviour. Leaders gain advance warning because the model spots issues long before teams notice them manually.

Generative AI in the supply chain turns every deviation into a structured risk marker for fast evaluation.

Examples of early risk indicators:

- supplier lead time drifting outside normal range

- port dwell time rising above the weekly baseline

- weather systems moving into a critical lane

- demand signals accelerating beyond the forecast

Step 3: The engine evaluates the cost and impact of every risk

AI in the supply chain scores each risk based on financial exposure, customer commitments and probability, and the same analytical discipline seen in AI manufacturing trends helps leaders gain clarity because the model prioritises disruptions worth acting on rather than flooding teams with noise. Each score shows potential cost impact so teams can decide where action prevents losses.

Each risk assessment includes:

- projected cost of delay or failure

- expected customer impact on OTIF commitments

- likelihood of escalation within the next planning cycle

- recommended urgency level for planner response

Step 4: The system generates the strongest action for your situation

The engine simulates multiple decisions and selects the option that protects your margin and service levels. Generative AI in the supply chain uses your constraints, carrier rules and sustainability goals to recommend the best move. Leaders receive decisions rooted in data, not assumptions, so planning teams act with confidence.

Options evaluated by the model include:

- rerouting through a faster and reliable lane

- shifting volume to a more stable supplier

- advancing planned production to avoid a shortage

- holding inventory to reduce unnecessary freight cost

- proposing a low-carbon alternative that meets policy requirements

Step 5: The recommended action lands directly with your team

AI in supply chain management sends a structured action message to planners or control tower leads. Your team receives a complete instruction rather than a vague alert, so execution happens quickly. Leaders gain predictable outcomes because every recommendation includes reasoning and expected results.

Action messages commonly include:

- detailed reroute guidance with expected transit time

- suggested carrier change with projected cost impact

- proposed rebalance between nodes with timing and volume

- clear expedite or hold instructions aligned with forecast

Step 6: The engine improves its accuracy after every outcome

The system updates its understanding based on accepted or rejected recommendations.

Your supply chain becomes stronger because the model incorporates real outcomes into future predictions.

Leaders gain a compounding advantage since accuracy improves every week across volumes, seasons and markets.

Learning updates include:

- revised lane performance based on recent events

- improved supplier reliability profiles

- updated forecast accuracy after demand shifts

- smarter prioritisation for future disruptions

AI in the supply chain delivers measurable value when every step in the operational cycle works together. Leaders gain stability because disruptions are detected early, scored with clarity, and resolved through a proactive reroute or recovery plan.

A supply chain that responds with that level of intelligence becomes predictable, profitable and ready to support growth without adding operational complexity. The same intelligence strengthens asset reliability through AI predictive maintenance and reduces preventable downtime.

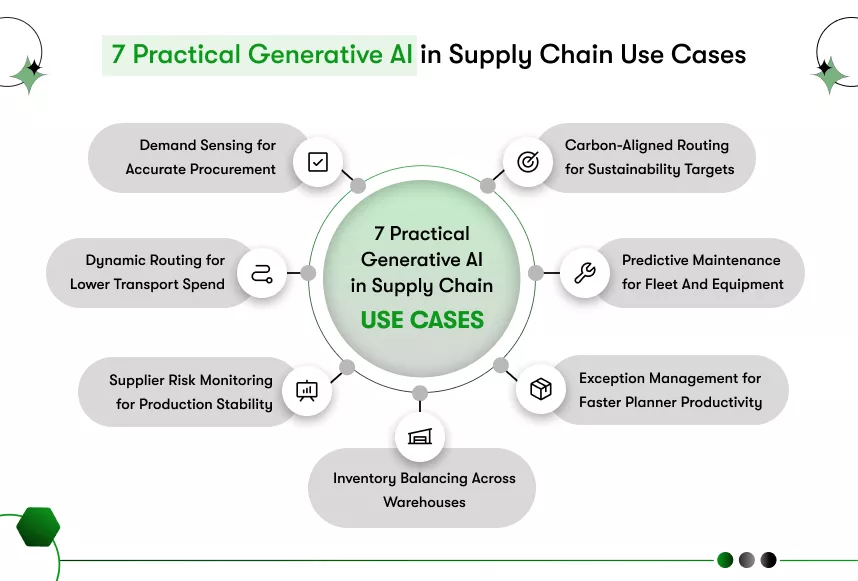

7 Practical Generative AI in Supply Chain Use Cases Your Team Can Deploy In 2026

You manage daily decisions across lanes, suppliers and orders, yet hidden risks still disrupt your targets. Leaders using AI in the supply chain for manufacturing remove that uncertainty with practical use cases that create measurable financial gains. Every example below shows how your operations shift from reacting to predicting.

Scroll, because your next optimization opportunity is already visible here.

Use Case 1: Demand Sensing for Accurate Procurement

You work with forecasts that change frequently, so your buyers commit too early or too late. Demand sensing uses your sell-through data, promotions, regional events and historical patterns to predict demand with greater confidence. You avoid the frequent swings that create excess stock or painful shortages.

How you gain stability:

- Forecast models respond to real demand signals instead of outdated averages.

- Short-term shifts in orders get tracked across SKUs to prevent stock imbalances.

- External inputs such as weather, events, and channel trends shape more accurate dispatch plans.

Outcome you can expect from demand sensing and accurate procurement:

Accurate demand sensing reduces unplanned orders and protects your purchasing budget from avoidable spikes.

Use Case 2: Dynamic Routing for Lower Transport Spend

You rely on fixed lanes that fail whenever a disruption hits a port or region. Dynamic routing evaluates capacity, dwell times, weather alerts and carrier reliability so you always move on the most dependable path. Your shipments stop depending on chance and start depending on intelligence.

How you gain control:

- Routes get evaluated continuously against port conditions, dwell time patterns, and lane delays.

- Each shipment gets a cost-to-service calculation to identify better lanes on time.

- Carriers and modes get compared in minutes to keep freight cost predictable.

Outcome you can expect from dynamic routing for lower transport spend:

Dynamic routing stabilises your network and avoids high-cost emergency moves that crush your margin.

Use Case 3: Supplier Risk Monitoring for Production Stability

You source from multiple vendors, yet small signals such as labour shortages or machine downtime often reach you too late. Supplier risk monitoring reads delivery behaviour, cycle times and exception history to detect risk early enough for you to react.

How you stay ahead:

- Supplier behaviour patterns highlight early warnings long before delays appear in reports.

- Lead-time variance gets measured against historic windows to surface threats early.

- External feeds such as labour alerts or regional weather form stronger risk profiles.

Outcome you can expect from supplier risk monitoring for production stability:

Early supplier visibility keeps your plants running and protects revenue tied to uninterrupted production.

Use Case 4: Inventory Balancing Across Warehouses

You hold stock across multiple nodes, but transfer decisions still depend on manual checks and delayed visibility. AI in the supply chain for manufacturing identifies shortages, surpluses, and nearby rebalancing opportunities in real time, so inventory moves faster and decisions no longer wait on spreadsheets.

How you unlock working capital:

- Line schedules align automatically with available capacity instead of static calendars.

- Upstream material visibility improves allocation for high-value orders.

- Production slots get protected by identifying bottlenecks before they escalate.

Outcome you can expect inventory balancing across warehouses:

Network-wide visibility reduces total holding cost while keeping customer availability strong.

Use Case 5: Exception Management for Faster Planner Productivity

You spend hours reviewing dashboards that show too many alerts. Exception management grades every issue by cost impact, urgency and service risk so you act on the few that matter.

How your team gains speed:

- Inventory positions sync with near-real-time consumption data.

- Excess stock risk decreases through targeted replenishment recommendations.

- Safety stock gets recalculated through live demand insights rather than fixed rules.

Outcome you can expect exception management for faster planner productivity:

Your team operates at a higher level without adding headcount or new workflows, and the benefits of AI in manufacturing reinforce this efficiency by supporting smoother coordination across operations.

Use Case 6: Predictive Maintenance for Fleet and Equipment

You depend on carrier reliability and internal handling equipment, yet failures appear without warning. Predictive maintenance reviews loading patterns, utilisation and runtime to highlight upcoming failures.

How your operations stay reliable predictive maintenance for fleet and equipment:

- Freight cost variance gets tracked lane-by-lane to prevent silent overspend.

- Spot quotes get compared instantly against historical benchmarks.

- Mode selection adapts automatically when cost thresholds rise.

Outcome you can expect:

Predictive maintenance keeps freight moving and avoids bills created by surprise downtime.

Use Case 7: Carbon-Aligned Routing for Sustainability Targets

You have sustainability goals linked to transport, yet manual carbon tracking is slow and inaccurate. Carbon-aligned routing suggests the cleanest lane that still protects your schedule.

How your carbon score improves:

- Carbon impact gets calculated for every route, carrier, and mode in advance.

- Low-emission alternatives become visible during routing decisions.

- Sustainability metrics get consolidated into a single view for audits.

Outcome you can expect from carbon-aligned routing for sustainability targets:

Carbon-aligned routing supports your sustainability strategy without sacrificing delivery speed.

AI in the supply chain proves its value when these use cases start delivering predictable savings and stable service levels. Leaders who adopt these capabilities build more reliable operations and create room for stronger margins.

Hypothetical Case Study: How AI in Supply Chain Works Inside a Real Operation

A mid-size component manufacturer in the USA, CentraParts, runs a stable network of three key suppliers, two regional warehouses, and one final assembly plant. The network appears predictable on paper, yet planners face late dispatches, route delays, short-notice line changes, and unplanned air freight every month.

These issues slowly raise cost-to-serve and increase risk exposure. The leadership team decides to run a controlled pilot of AI in supply chain management to understand how real-time intelligence changes daily execution.

Step 1: Data from core systems enters the AI layer in supply chain

ERP updates, WMS orders, TMS events, and shipment timelines flow into one model. The team does not create new reports. The intelligence layer studies every update as soon as it appears.

Step 2: The model detects operational risk signals

The engine reviews historical performance and compares it with today’s movement. When supplier loading time extends beyond the usual range or when port dwell time rises above baseline, the system flags those deviations as early risk indicators.

Step 3: The engine scores each risk based on cash exposure

Every deviation receives a score that reflects its impact on fulfilment, cost, working capital, and service commitments. High-score events move to the top of the dashboard so planners are not flooded with noise.

Step 4: The model simulates alternatives before the disruption escalates

The system runs hundreds of scenarios in minutes. It evaluates alternate carriers, regional warehouses, cross-dock combinations, and nearby ports. The generative engine suggests the fastest lane, the lowest-risk consolidation, and the most stable routing plan. This is where generative AI in the supply chain delivers value: it proposes options that the team would require hours to calculate manually.

Step 5: The recommended action is delivered with full cost visibility

The intelligence layer presents a single recommended action. It includes travel time, cost variation, carbon impact, inventory change, and OTIF implications. Planners get the full breakdown in one screen, instead of stitching data across five tools.

Step 6: The team approves the action and execution begins

Once the team approves the recommendation, the workflow updates the respective carrier or supplier. The plant gets a revised ETA, production schedules adjust smoothly, and downstream commitments stay on track.

Step 7: The system learns from every decision

The engine observes which actions the team accepts and which ones they replace. It trains on these choices, gradually improving the accuracy of future recommendations. Over a few weeks, routing, scheduling, and exception handling become more predictable.

This hypothetical case study shows how AI in the supply chain converts complex daily operations into stable, predictable performance. The manufacturer gained early visibility, avoided unplanned cost spikes and protected critical service levels without expanding its team.

The same workflow benefits any organisation that depends on accurate planning and uninterrupted material flow, especially when teams choose to hire AI developers who understand operational realities and build systems that scale with them. When these AI-driven processes run inside your network, every decision becomes sharper, response time drops and financial outcomes improve with consistency.

As AI in logistics and supply chain evolves, the future of AI in supply chain will reward teams that act early and build strategic visibility.

How Can AI Enhance Sustainability in Supply Chain Operations?

AI in supply chain management improves sustainability through lower emissions, smarter energy use, and clearer control over carbon-heavy choices. You get more stability because AI connects routing, inventory, transport and vendor activity into a single real-time view that exposes where waste starts and where reductions create genuine financial return.

You’ll now see how AI in logistics and supply chain strengthens sustainability across everyday operations, and how each improvement delivers measurable cost savings, carbon reduction, and supports the future of AI in supply chain performance.

Carbon-Aware Route Planning

AI models evaluate distance, dwell time, weather, congestion, and carrier emissions to identify routes with the lowest environmental impact. You gain early visibility into the carbon difference between options instead of choosing only on cost or speed.

- AI compares multiple lanes and calculates carbon output for each route with complete accuracy.

- The system prioritises lanes that reduce unnecessary fuel burn without risking delivery commitments.

- Real-time visibility supports faster decisions when ports, hubs, or cross-docks create delays that increase emissions.

You make routing choices that lower emissions while protecting reliability. This improves sustainability without forcing trade-offs you cannot defend to customers or leadership.

Load Optimization to Reduce Empty Miles

AI reviews shipment volumes, weight distribution, order timing, and historical utilisation patterns. It then recommends how to increase fill rates and reduce transport that runs half-empty.

- The system analyses SKU mix, pallet patterns, and lane demand to raise average utilisation.

- Machine learning highlights repeat behaviours that create empty miles and offers corrective actions before dispatch.

- Better predictions mean fewer trucks running with space that turns into waste.

Higher utilisation reduces emissions per shipment and improves transport efficiency without adding new assets.

Automated Consolidation Models

Generative AI in supply chain operations identifies consolidation windows across multiple orders, suppliers, and delivery zones. You receive recommendations that align inventory timing with smart bundling.

- AI finds consolidation opportunities missed by manual planning due to timing gaps or dispersed suppliers.

- Models understand acceptable delays that still protect service levels while reducing vehicle movement.

- The system aligns consolidation with carrier capacity to avoid unnecessary runs.

Smart consolidation lowers emissions, fuel consumption, and handling costs while maintaining predictable flow.

AI-Driven Energy Optimisation in Warehouses

AI tracks consumption patterns across lighting, HVAC, automation systems, and equipment cycles. Models then guide adjustments that reduce waste without interrupting site operations.

- AI identifies energy spikes linked to shift patterns, idle machinery, or inefficient automation schedules.

- Predictive models reduce consumption during low-activity periods without harming throughput.

- Visibility across assets helps leadership justify targeted upgrades instead of expensive full-site changes.

Warehouses consume significant energy, and AI gives you the control needed to lower operational carbon footprint with confidence.

Vendor Scoring Based on Carbon Impact

AI in supply chain examples increasingly highlight vendor scoring as a core sustainability lever. Models evaluate supplier emissions, delivery reliability, defect rates, and transport distance to determine true environmental cost.

- AI combines operational data and environmental metrics to rank suppliers fairly and transparently.

- Vendor scoring highlights hidden carbon hotspots in your network, especially in high-volume categories.

- You gain a factual basis for sourcing decisions aligned with sustainability goals.

Vendor choices shape most of the upstream carbon footprint. AI helps you select partners who strengthen both performance and sustainability.

AI in logistics and supply chain operations strengthens sustainability by improving routing, utilisation, consolidation, energy use, and vendor selection. You gain accurate insights that support environmental goals without raising cost or complexity, especially when supported through expert AI development services that align the models with your operational needs.

These improvements show where the future of AI in the supply chain will deliver the strongest environmental and financial advantage.

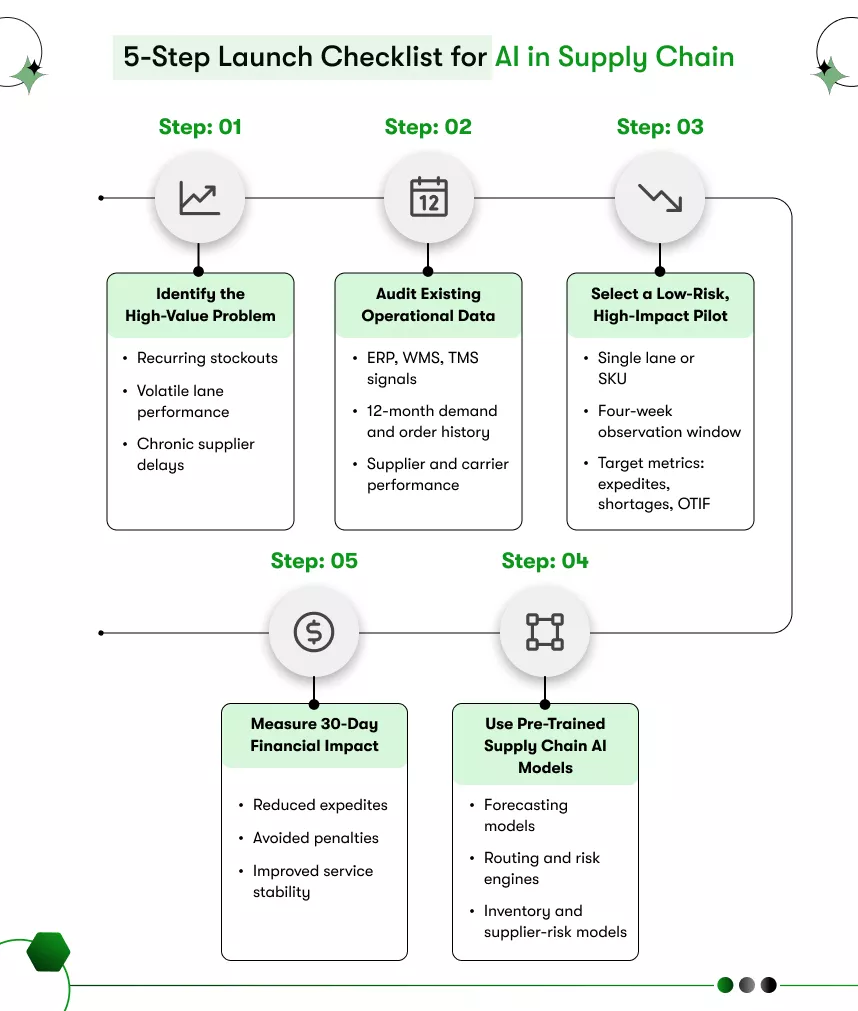

A Proven 5-Step Checklist to Begin AI in Supply Chain Without Risk

AI in supply chain management delivers results only when leaders follow a structured launch plan instead of experimenting with scattered pilots. The checklist below gives you a clear pathway that avoids delays and shows predictable ROI.

Scroll through each step because every stage links directly to money saved and risk removed.

Step 1: Confirm the One Problem Worth Solving First

Every successful AI rollout starts with clarity. You identify a single problem that drains margin or disrupts flow. The best starting points include recurring stockouts, volatile lane performance, or chronic supplier delays. When one problem carries a clear cost, AI in the supply chain generates measurable improvements from day one.

- Select a problem where the financial loss exceeds fifty thousand dollars each quarter.

- Validate that the problem repeats often enough to justify automation.

- Map who owns this process today and how decisions are currently made.

A clear problem prevents wasted budget and helps your team see early wins quickly.

Step 2: Audit the Data Already Inside Your Systems

You do not start by collecting new data. You begin with the information already stored inside your ERP, WMS, TMS and planning tools. Most organisations have enough signals to train strong models, and this step proves exactly where the backbone of AI in logistics and supply chain will operate.

- Pull twelve months of demand, orders, routes, carrier performance and supplier history.

- Identify fields with gaps, delays, duplicates or inconsistent naming patterns.

- Validate the frequency of updates so your AI models do not depend on stale inputs.

A structured data audit gives your technical partner the confidence to build reliable predictions without chasing missing fields later.

Step 3: Pick a Pilot Lens That Reduces Risk and Shows Fast ROI

Different supply chain issues require different AI approaches. Predictive models forecast risk. Prescriptive models suggest the best response. Generative AI in supply chain scenarios builds multiple future options and selects the most resilient path. Matching the model to the problem ensures relevant and defensible recommendations.

- Choose a lane or SKU that already has measurable disruption patterns.

- Set a four-week observation window to capture baselines and early shifts.

- Define a target metric such as reduced expedites, fewer shortages or improved OTIF.

A controlled pilot builds organisational confidence and gives you clean success signals to present to senior leadership.

Step 4: Deploy a Pre-Trained Model Instead of Building Custom Code

You accelerate results when you rely on proven models rather than building algorithms from scratch. Modern platforms offer pre-trained engines tailored for AI in supply chain management, allowing your team to evaluate value in weeks instead of months. This reduces implementation risk and keeps cost predictable.

- Select a model aligned with forecasting, routing, supplier risk or inventory control.

- Validate the model with a backtest using your last six months of operational data.

- Review the model’s action recommendations with planners before enabling automation.

Pre-trained models shorten timelines and remove engineering uncertainty, helping you scale faster.

Step 5: Track Financial and Operational Gains for the First 30 Days

This step proves the ROI. Once recommendations begin flowing, your team measures saved cost, recovered service levels and avoided disruptions. Leaders use this phase to quantify how AI in the supply chain improves margin, stability and weekly decision speed.

- Compare the number of expedites before and after the model went live.

- Calculate avoided penalties, reduced rebooking charges and shrinkage in safety stock.

- Document every early warning that protected service levels during high-risk periods.

A thirty-day results review creates a repeatable business case that supports expansion to more lanes, suppliers and networks.

This five-step checklist gives you a controlled path to launch AI in supply chain programs with clarity and confidence. You begin with a focused area, prove measurable value, and expand with evidence instead of assumptions.

When leaders follow this approach, AI adoption becomes a business decision that protects margin, strengthens resilience, and drives faster operational flow.

Conclusion

Supply chain pressure never slows down, and teams who rely only on dashboards and delayed reports keep paying for surprises they could have prevented. AI in supply chain management changes that pattern by giving your planners early signals, accurate scenarios, and stable cost control long before a disruption reaches your network.

You now understand how the right models, real-time signals, and structured workflows protect service levels and unlock predictable margin. The companies adopting these systems early will define the future of AI in the supply chain because they operate with clearer visibility, faster decisions, and measurable performance gains.

If you want the same advantage without building everything from scratch, Kody Technolab guides you through each step. You get practical use cases, supply-chain-ready AI models, and a deployment plan that fits your data, your lanes, and your budget. When you partner with Kody, your supply chain becomes stronger, calmer, and consistently profitable.

FAQs

1. How do I know if my organisation is actually ready for AI in supply chain management?

Readiness comes from clean operational data, stable process owners, and a clear cost target. If your team understands the current pain areas and has at least twelve months of historical data, you are ready to begin. A structured pilot reduces risk and shows value within weeks.

2. What is the real investment required to start? Do I need a full data science team?

Most companies begin with a SaaS model and avoid large upfront costs. Modern platforms include pre-trained AI models, so no internal data science team is required. The main investment is data preparation and change management, which is predictable and usually lower than expected.

3. How quickly can AI in logistics and supply chain show measurable financial impact?

Teams often see measurable changes within the first sixty to ninety days of a focused pilot. Early visibility into delays, demand shifts, and capacity changes reduces unplanned air freight and excess inventory, which creates direct savings.

4. What mistakes cause AI pilots to fail inside supply chain operations?

Pilots fail when the team tries to automate everything at once. Success requires one clear objective, one owner, and one well-defined lane or SKU. Another common issue is poor integration with existing systems. A strong workflow design prevents this.

5. Can AI create problems if my processes are not standardised yet?

AI can still work with imperfect processes, but unclear ownership slows adoption. A short process mapping exercise helps unify TMS, WMS, and ERP events so the AI model reads data consistently. Once alignment is complete, output quality improves rapidly.

6. How do I measure the ROI of AI in supply chain examples without relying only on cost savings?

ROI includes avoided disruptions, reduced carbon footprint, fewer manual hours, and improved customer service levels. Many organisations also measure the stability of forecast accuracy and the consistency of OTIF performance.

7. Will AI limit my team’s judgement or decision control?

AI supports decision makers. It flags risks early, ranks options and predicts outcomes. The final decision stays with planners and managers. Over time, users trust the system because recommendations remain consistent with operational priorities.

8. How does AI protect sensitive operational data when cloud systems are involved?

Modern AI platforms use strict access controls, encryption, audit logs and region-locked data storage. Vendors also follow SOC 2, ISO 27001 and GDPR practices. Data remains in secure environments with no exposure to public models.

9. How can I ensure AI tools remain accurate during rapid market changes?

A good platform retrains its model with your latest operational data. This adaptive behaviour keeps predictions aligned with new supplier performance, seasonal patterns or demand trends.

10. What should my first 90-day roadmap look like if I want real results?

Start with a clear goal, choose a high-impact lane, connect data sources, deploy the model, validate outputs with planners and measure cost, time and carbon improvements. A structured 90-day setup builds the foundation for scaling advanced use cases.

Contact Information

Contact Information