Summary: Digital Twin Use Cases in Manufacturinghelp leaders uncover hidden inefficiencies, prevent breakdowns, and avoid costly production mistakes. This blog explains how virtual factory models solve real problems like downtime, quality loss, and waste. You’ll see practical use cases, real-world results, and clear paths to improve efficiency without disrupting live operations.

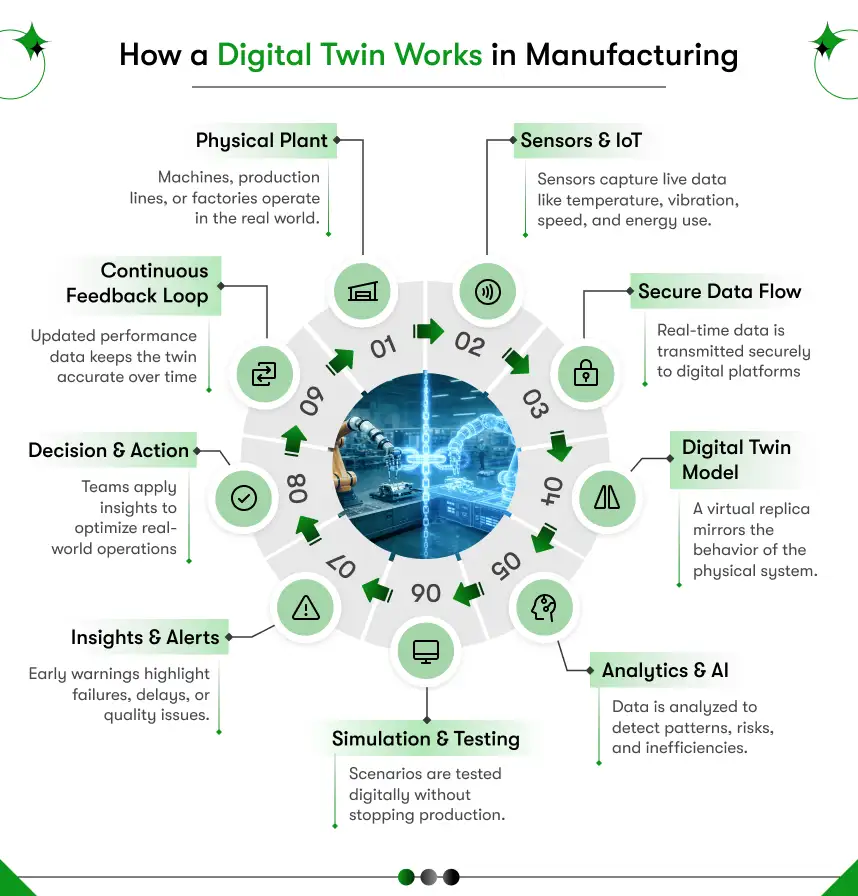

Today, factory leaders face constant pressure to minimize stoppages and defects, remain compliant, and even increase profits. A shipment, a failed batch, a delay, etc., is not only damaging margins but also rattling customers. Even brief disruptions can cost up to 260,000 US dollars per hour, whilst unplanned interruptions in large manufacturing enterprises can be even more expensive. Here, the use case of a digital twin in manufacturing begins to demonstrate its value. Simulated models of equipment, production lines, or even whole plants work alongside the real ones, capturing real-time behavior and showing the problem before it becomes critical, particularly when supported by the suggestions offered by an AI in Manufacturing guide.

Through testing in a virtual environment, teams can identify problems in time, make effective decisions, and drive improvement without affecting real production. Examples of digital twins in manufacturing across industries demonstrate physical benefits, including predicting equipment failures, reducing waste, and accelerating decision-making through data linking between departments. These are not technology demonstrations but practical tools that provide efficiency, reliability, and control in day-to-day operations.

What are the Best 10 Digital Twins Use Cases in Manufacturing?

Suppose a factory were replicated in a computer. An application of this in real-life plants is already being utilized to address daily operational problems and would also serve as a use case of digital twins in manufacturing. Rather than using conjectures, teams look at real data streaming into models that reflect real machines, and it is now possible to identify the issues in time before they become overwhelming, particularly when implemented as a component of a digital twin in manufacturing projects.

These systems link shop-floor sensors to analytical systems. In some teams, redesigning assembly lines based on performance data, whereas others monitor energy consumption to minimize waste. Early testing enhances adaptability, reduces delays, and stabilizes output regardless of the scale of the single process or whole operation. The worth lies in its ability to represent the actual physical reality, not in its complexity.

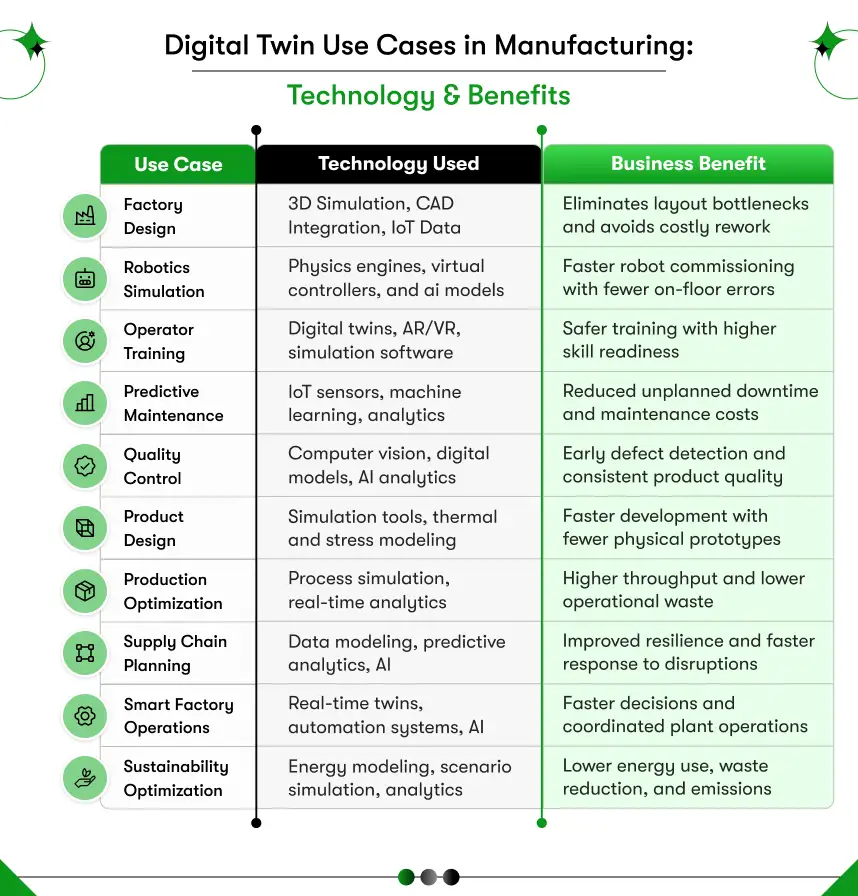

Factory Design

Before any actual adjustment is made in real life, a digital copy of the factories is created as part of digital twin use cases in manufacturing. This copy exists on computers, demonstrating how machines and workers are integrated in unison. Planners do not make guesses about what is working; they experiment with layouts on a computer. When something needs to be shifted, they do it digitally; no tools are needed. Mistakes are presented at the beginning, and wasted time is saved. Throughout the period, the entire process is test run without coming into contact with steel or concrete. Suppose there were machines here?

Testing positions virtually indicate areas where the speed slows. Anything that moves workers through the space will reveal concealed threats before anyone is injured. Long-type routes are of materials that are noticeable when plotted beforehand. There is another route that could save time and reduce exhaustion. Probing out one setup after another on the screen saves the expensive rebuild later. The most effective design does not need to stop production. Space that seemed unusable is now accommodating a new purpose, especially when supported by digital twin solutions for manufacturing.

Consider the Siemens plant in Amberg, where machines there became smarter when virtual copies informed modifications, increasing output by about a fifth. The use of rooms increased by nearly five out of ten square meters, attaining a purpose. Options in construction design changed and were influenced by actual values rather than estimates. In manufacturing, design is everything. At the initial stages of a factory organization, it is better to shape the layout and determine the performance; digital twins can ensure that employees are not harmed and have space to expand. This arrangement not only addresses issues but also prevents them before they start.

Robotics Simulation

One robot may train movements within a computer world, which is a replica of real conditions, without the physical machines being in operation, and this is one of the practical digital twin use cases in manufacturing.

The robot’s movements are tested before being sent onto the factory floor to ensure people’s safety. Problems become manifested earlier when engineers model what they are doing. Errors are identified without endangering losses or time. Digital runs help identify future crashes. Virtual trials are the most effective in complex setups. Minimal surprises result in shorter setup times. Money is saved by avoiding on-site rework. This is where comparisons like Digital Twin vs Traditional Simulation become relevant, as live-linked models continue learning while static simulations do not.

One error on the factory floor can delay as simulations are carried out first. Teamwork optimizes robot movements in virtual replicas, with no hiccups in the real world. Setups are shifted in software, not on live machines. The rollout of new products will accelerate, as the testing phase is not associated with a physical trial. Errors are instructive sooner, before the hardware is burdened. Some factories could use a clean slate; simulated robots in virtual tests reduce the amount of time spent on error reduction before the actual installation is attempted. Once machines are installed, changes on the floor lead to smoother machine operation. Fewer surprises occur in shifts since issues have been resolved in a digital environment. In this manner, production does not come to an abrupt stop, slowing it down.

Quality Control

Digital twins can be used in quality control to work in the background, so to speak, as an additional inspector that does not get fatigued, forming one of the most practical digital twin use cases in manufacturing. Live data is verified against a computer representation of the appearance of things as production runs. Even a minor change begins to show, often before a malfunction progresses further.

The sensors continue feeding measurements continuously, and over time, the system becomes aware of what normal actually is for that process. Once it starts to wander, the teams have a warning that allows them to intervene in time. Scrap and rework are reduced, and fewer problems reach customers.

The largest distinction is that there is no production halt as quality is improved. Consistency is ensured even as the work continues to flow, without halting the line for an investigation.

Product Design

Before a single piece was assembled, digital versions allowed engineers to see how things could operate. Testing is done earlier because simulations are used to evaluate performance under stress. Unless changes are tested by building something real, ideas evolve more slowly. Stress, heat patterns, and real-world performance are all evaluated in advance, often alongside broader software initiatives outlined in an AI app development guide. With faster results, decisions become sharper, and there are fewer delays during build phases. Fewer trials and errors will result in fewer wastes accumulating.

One of the tests could be conducted on a computer rather than on the sidewalks. Risks in the real world are reduced when engineers make design adjustments virtually. Speed does not come in haste, but by first rehearsing each detail. Errors manifest themselves sooner and are corrected before metal bends. Faith is cultivated since systems have evidenced themselves even before production. In other words, product design becomes faster and cheaper when digital twins are used at the core of the creation process.

Production Optimization

Detailed simulated factory models allow teams to test changes without involving the actual machines, making this one of the most results-driven digital twin use cases in manufacturing. These computer clones demonstrate the effects of setting changes on the assembly floor before anything is applied in the real world, often as part of broader Digital Twin Solutions for Manufacturingstrategies.

A new adjustment in manufacturing, such as changing a shift period or a batch quantity, is reflected in real time in the output rate, scrap materials, or electricity consumption. One develops confidence in making decisions based on observable results rather than intuition. More speedy adjustments are made to the situations when companies such as Tesla rely on simulations to optimize manufacturing. There is a reduction in waste since production better aligns with real needs. There is a flow of operations, and it is just a matter of smarter planning. Stability is enhanced not by chance, but through testing in virtual environments repeatedly.

In conclusion, factories can use digital models to refine output, keeping machinery operating smoothly while staying within safety margins. Productivity increases not through coercion, but through intelligent modifications inherent in the operations system.

Supply Chain Management

Digital copies help trace materials in the event of an accident before they enter production lines. In certain cases, these models are depicted with delays even before they are anticipated. Beginning with supplier behavior, companies map delivery routes and check stock levels to identify potential issues, especially when aligned with broader planning strategies, such as AI for supply chain initiatives.

Teams also test different means of sourcing or moving materials before issues get out of hand, rather than responding to the situation late. Due to this change, operations across the various locations are quicker to respond to unprecedented events. The use of backup options helps to advance and sharpen the planning and decreases disruption.

Facing shifting demand? Unilever is relying on digital twins to maintain output worldwide. These virtual models are connected to factories where supply is synchronized with demand. Systems are flexible and keep time as orders increase or decrease. Coordination occurs in real-time, site to site. The output remains a predictable and steady output, all the time. Finally, factories in the supply chain can be more adaptable with the help of digital twins in case conditions change suddenly.

Smart Factory Operations

Before each movement is made, a computer-generated copy takes the machinery through decisions by the second. Smart factory operations are one of the most advanced use cases of digital twins in manufacturing. Robots respond to real-time reports from their online counterparts rather than waiting. The inspection systems identify defects as soon as they are present, and the information is relayed back immediately. At the same time, transportation within the company constantly changes routes and is synchronized by an invisible model that is one step ahead.

Out there, machines feed off live data through sensor routes that twist and turn, inspections change automatically, and goods are shipped immediately. The place just goes with it, no slip behind. The cooperation between companies like NVIDIA and Siemens demonstrates what can be done: digital models that replicate real-life systems and can be altered in real time. Such reflected systems continuously feed data back into decision-making, refining day-to-day operations. A digital twin brings automation, data, and control together into a single, seamless setup for smarter factory work.

It is a flow that bears a connection, and the pieces fit together. This type of system operates on live updates rather than guesswork. Every section is addressing another as members of a team who know the scheme. Naturally, coordination results when everyone agrees. The factories begin to accelerate as delays are reduced. The decisions are not made slowly; they are made instantly. The entire process does not seem like button pushing but more like momentum guiding.

Sustainability Efforts

Digital twins are constructed to replicate real-life systems and identify opportunities to reduce energy consumption, waste, and even pollution, making sustainability one of the growing Digital twin use cases in manufacturing and a clear example of applications of digital twins in manufacturing. Their influence may be invisible, but it manifests where needed, i.e., there is less strain on resources, and the way ahead is clearer.

Operations before rollout. Fine-tuning operations allow producers to predict power requirements, experiment with upgrades to improve performance, and test the effects of shifts on emissions. Suddenly, becoming green is tracked, rather than being an idea on paper. The Unilever factories operate more efficiently thanks to simulated scenarios; every test improves machine performance. As these models reflect actual production lines, cleaner operations can be developed without slowing output. Industrial clones demonstrate that there is at least one thing that does not require a fortune to provide better results.

Altogether, digital twins designed for sustainability enable makers to achieve sustainability goals without further slowing operations.

How to Implement these Digital Twin Use Cases in Manufacturing?

One slip will turn months of work upside down, and matching actual machines with the virtual ones must be staged. Slow development can help factories prevent costly mistakes in construction while building trust among employees as they proceed, rather than gambling on techno-hype. Measure the assets, gather data.

Determine the assets, gather IoT data.

Begin by identifying some of the critical equipment or work processes where quality, stoppages, or regulations are most important. The next step would be to install sensors and related equipment to obtain real-time measurements of heat, movement, output, and power. This data becomes the foundation for digital twin manufacturing use cases, ensuring models reflect actual operating conditions rather than assumptions.

Create a simulation model using programmes.

Engineers create digital twins in simulation software, beginning with clear data inputs, which form a core part of digital twin use cases in manufacturing. These replicas help crews assess equipment performance under pressure because they reflect real-life operations. The system updates in real time as conditions change; there is no need for downtime to test these changes. Patterns in the workflow become apparent, and bottlenecks are identified before they cause delays. Machines behave as they do on the floor and respond to simulated stress in the same way as live systems behave. This arrangement ensures that planning is done before execution, without incurring the expense of trial and error.

Implement analytics to perform real-time syncing.

Individuals begin with live feeds, which combine with machine learning within the digital twin. As a result of this connection, predictions are made, and strange patterns are identified in the initial stages. When models become self-adaptive, it becomes possible to test various scenarios, which is one of the practical applications of digital twins in manufacturing. What once remained static now evolves with every new piece of information, supported by implementation capabilities often delivered through AI Development Services.

Train Teams Monitor KPIs

Its effectiveness depends largely on the team that applies it, not on the tool itself. Individuals who are involved in day-to-day activities learn how the digital model helps them. The routines are modified based on what maintenance crews uncover over time. Live data feeds help make quality checks keener. These improvements are reflected in figures such as machine idle time. Fewer defects are being created in production because the feedback loops remain active. The trend in energy use can be used to identify areas where savings can be achieved. When results reflect real performance change, long-term value is achieved with support from a Generative AI development company to scale these systems effectively, as they are experts in the field.

In conclusion, digital twins in factories can be useful in the long run, rather than being discarded into oblivion when implemented piecemeal.

Real-World Examples of Digital Twins in Manufacturing

Real-world results are where digital twins move from theory into practice. Manufacturers across industries are using virtual models as everyday tools to solve familiar problems such as delays, breakdowns, inefficiencies, and downtime. The examples below show how digital twins use cases are applied in real operating environments, making it an efficient example.

| Company | Use Case | How Digital Twins Were Applied | Measurable Business Impact |

| BMW | Product Design & Testing | Virtual vehicle models were used to simulate performance, safety, and stress conditions before physical prototypes were built. | Reduced physical prototypes, faster development cycles, and improved vehicle safety. |

| Caterpillar | Predictive Maintenance | Equipment twins monitored real-time sensor data to predict failures and proactively schedule maintenance. | Higher equipment uptime, lower maintenance costs, and fewer unplanned breakdowns. |

| Tesla | Production Optimization | Assembly line twins simulated throughput, layout changes, and demand scenarios. | Reduced waste, improved line efficiency, and better demand alignment. |

| Unilever | Supply Chain & Sustainability | Factory and supply chain twins tested production scenarios and energy optimization strategies. | Improved OEE, reduced energy usage, and more consistent global production. |

What stands out across these real-world examples is the outcomes these technologies enable. Fewer breakdowns lead to smoother production and better resource use, all of which result from clearer oversight of operations before problems escalate.

What are the Troubles Ahead in Digital Twin Use Cases in Manufacturing and What Lies Next?

Although they are helpful, digital twin use cases in manufacturing come with challenges that factory leaders must consider in advance.

Factories connecting like never before; security cannot be an exception. In machine-to-machine communication, protecting sensitive information requires clear regulations and robust technical safeguards. What may work on one machine may not work at scale; when expanding twin systems across sites, it is necessary to handle all the steps. Performance slipping? Such hazards increase as networks go too fast.

By 2027, digital twin use cases in manufacturing should increasingly rely on artificial intelligence. They would not be content only to monitor performance or predict problems, but would be in a position to influence decisions or even make decisions themselves, immediately. Factories need not be as slow to adapt or be self-managed, as these models connect with smarter robots and self-managing systems. The change could restructure the responsiveness of production lines to day-to-day changes.

Despite the obstacles, one thing is noticeable: smarter forms, tailored more closely to factory planning, and increasingly connected across systems.

Final Thoughts

It is a new perspective on factory processes, with virtual replicas of machines that were previously only theoretical; now, these models allow teams to address problems before they proliferate. Digital twin use cases in manufacturing enable leaders to move away from guesswork and rely on real-time operational insights when building products, running lines, managing waste, maintaining quality, and keeping equipment ready. When time is scarce, regulations become stricter, and costs are rising, managers resort to such systems to have a clear picture of what is happening where. The individual stages of the creation become better understood, increasingly smooth, and less unexpected.

Running smoothly isn’t luck. Kody Technolab Ltd. develops systems that expand with needs, intelligent devices that evolve, and machines that become adaptable, connecting digital models with physical operations. Organizations that invest in the right expertise, whether through internal teams or by choosing to hire AI Developers, are better positioned to turn digital twins into long-term operational assets rather than short-term experiments. As a leader, you’ll treat this as your priority as it reduces your plant efficiency with fewer errors, downtimes, and better smooth production, and these use cases of digital twin in manufacturing become what gets you going.

FAQ

1. What are digital twin use cases in manufacturing?

Digital twin use cases in manufacturing involve creating virtual replicas of machines, production lines, or entire factories to monitor performance, predict failures, improve quality, and optimize operations. These use cases help manufacturers make data-driven decisions while reducing downtime, defects, and operational risk.

2. How do digital twins help reduce unplanned downtime?

Digital twins reduce downtime by continuously monitoring equipment health using real-time sensor data. By identifying abnormal patterns early, manufacturers can schedule maintenance before failures occur, avoiding costly breakdowns and production losses.

3. Are digital twins suitable only for large manufacturing enterprises?

No, applications of digital twins in manufacturing are scalable and can be implemented gradually. Many companies start with a single machine or line and expand over time, making digital twins practical for mid-sized manufacturers as well.

4. What data is required to build a digital twin in manufacturing?

Digital twins typically rely on IoT sensor data, including temperature, vibration, energy consumption, throughput, and quality metrics. The accuracy of digital twin manufacturing use cases depends on data quality rather than data volume.

5. How long does it take to see ROI from digital twin implementation?

Most manufacturers begin to see measurable benefits within a few months, especially in predictive maintenance and quality control. Faster decision-making, reduced rework, and lower downtime contribute to early returns on investment.

6. Can digital twins improve product quality and compliance?

Yes, digital twins compare real production data with ideal digital models to detect deviations in real time. This helps quality teams catch defects early, maintain consistent standards, and meet regulatory compliance requirements more effectively.

7. What challenges should manufacturers expect when adopting digital twins?

Common challenges include data integration, cybersecurity concerns, and change management. However, these can be addressed with phased implementation, secure architectures, and proper team training to ensure long-term success.

8. How do digital twins support future smart factory initiatives?

Digital twin use cases in manufacturing form the foundation of smart factories by enabling real-time monitoring, simulation, and optimization. As AI and automation mature, digital twins will play a key role in autonomous decision-making and continuous improvement.

Contact Information

Contact Information