Quick Summary: This blog shows how generative AI actually works inside manufacturing plants to move real KPIs. Learn where value appears first, how decisions improve before problems surface, and what a low-risk 30-day pilot looks like. Practical examples, clear execution paths, and measurable outcomes guide leaders from curiosity to confident action.

Generative AI in manufacturing feels like the extra shift that never shows up on your payroll. It works weekends inside trial licenses, trims fixture hours while downtime stays under review, and lets your night crews generate tool paths without overtime slips. You see the impact every time a line stops and someone reaches for a spreadsheet, every time inventory climbs even though order volume stays flat, and every time finance asks why your scrap budget keeps expanding.

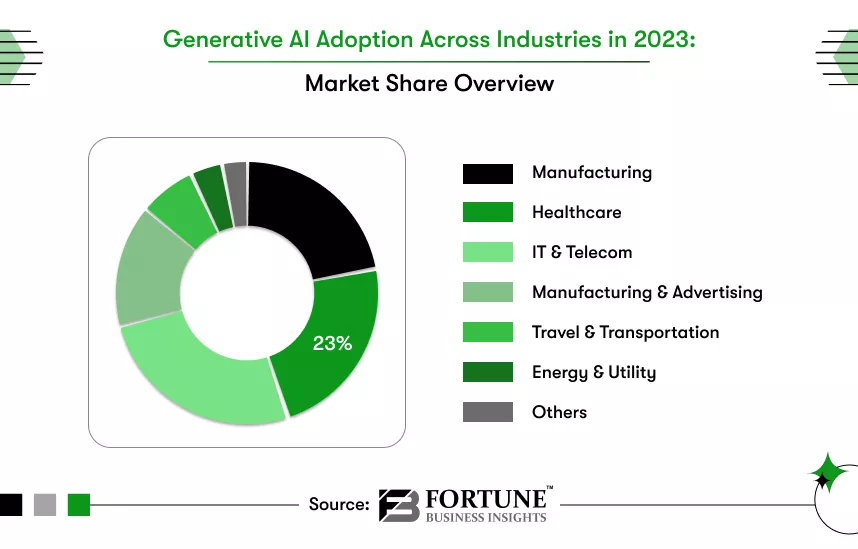

Those pressures land as unexplained overtime and scrap dollars that should have stayed in house. While you chase the leak, the generative AI in the manufacturing market has already grown from USD 43.87 billion in 2023 to a projected USD 967.65 billion by 2032, with North America taking nearly half. That capital buys decision speed, not slide decks, and turns it into margin you can bank. (Source: fortune business insights)

Stay with us for the next few minutes and you’ll see where generative AI use cases land on your floor, what integration really costs, and how to turn a pilot into extra throughput without buying another machine.

If you want to implement generative AI in your manufacturing operations but are unsure where or how to start, read our AI app development guide to get a clear, practical roadmap.

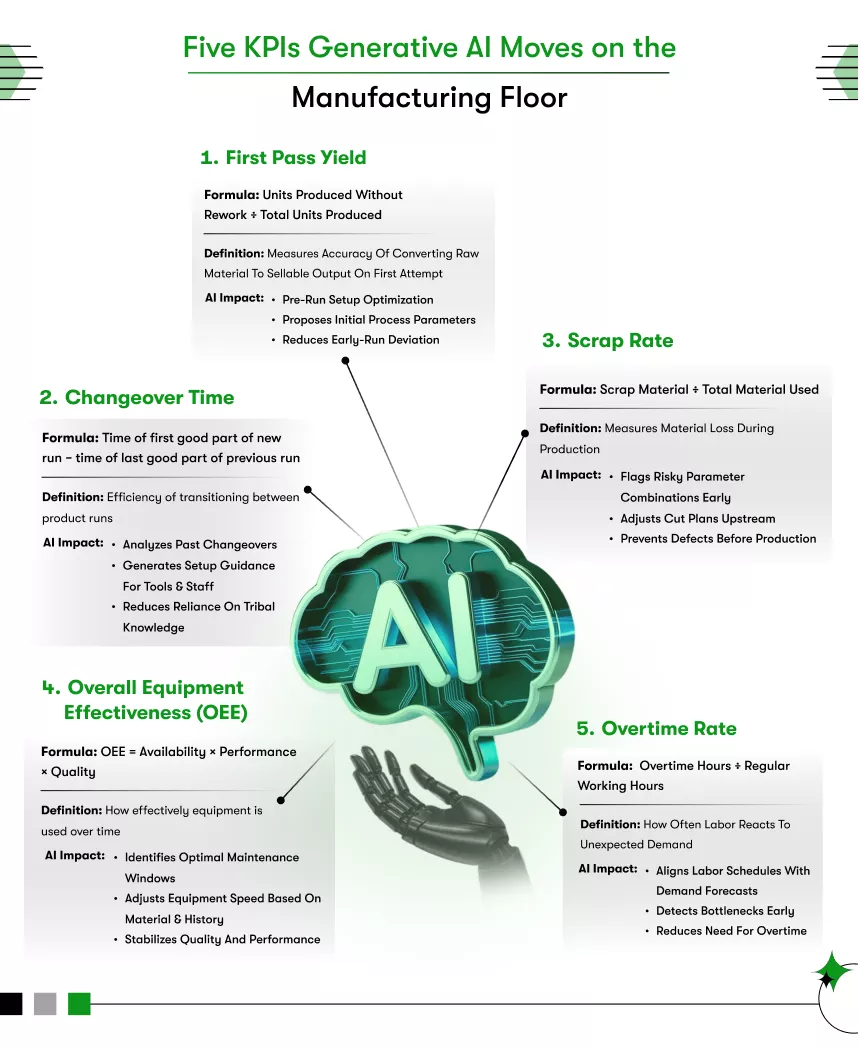

Five KPIs Generative AI Moves on the Manufacturing Floor

Manufacturing leaders already track these KPIs in weekly and monthly reviews. The formulas are familiar and unchanged. What improves with generative AI in manufacturing is the quality of decisions made before these numbers start to move inside a manufacturing plant.

1. First Pass Yield

Formula: First Pass Yield = Units produced without rework ÷ Total units produced

First Pass Yield measures how accurately a manufacturing plant converts raw material into sellable output on the first attempt. When yield drops, the issue usually originates before the first part is produced, not during inspection.

Where generative AI intervenes in production setup decisions

- During pre-run setup, generative AI evaluates historical production runs, tooling changes, and material certificates.

- Before machines start, the system proposes initial process parameters aligned with engineering intent.

- Setup decisions improve before operators compensate manually on the floor.

- These generative AI in manufacturing examples focus on reducing early-run deviation rather than correcting defects later.

2. Changeover Time

Formula: Changeover Time = Time of first good part of new run − Time of last good part of previous run

Changeover Time reflects how efficiently a manufacturing plant transitions between product runs. Delays usually stem from mismatched assumptions rather than missing procedures.

Where generative AI supports changeover planning and execution

- Before a changeover begins, generative AI analyzes past changeovers under similar tooling and staffing conditions.

- The system generates setup guidance matched to the current tool list, fixture availability, and operator skill mix.

- Crews receive instructions grounded in proven execution, not generic SOPs.

- One of the practical benefits of generative AI in manufacturing is reduced reliance on informal tribal knowledge.

3. Scrap Rate

Formula: Scrap Rate = Scrap material ÷ Total material used

Scrap Rate captures material loss during production. Scrap often increases when small process deviations compound across shifts and batches.

Where generative AI reduces scrap before material enters production

- During production planning, generative AI evaluates historical relationships between speed, temperature, tooling, and defects.

- Risky parameter combinations are flagged before material is processed.

- Cut plans and sequences adjust upstream instead of reacting during inspection.

- These generative AI in manufacturing use cases emphasize prevention rather than post-production analysis.

4. Overall Equipment Effectiveness (OEE)

Formula: OEE = Availability × Performance × Quality

OEE reflects how effectively a manufacturing plant uses equipment over time. Improving OEE requires balancing competing constraints rather than maximizing a single metric.

Where generative AI supports equipment-level decision tradeoffs

- During scheduling, generative AI identifies maintenance windows that minimize production disruption.

- Equipment speed profiles adjust based on material grade and historical performance patterns.

- Quality parameters stay aligned with performance targets through contextual guidance.

- Manufacturing leaders gain clearer insight into which decisions stabilize OEE and which introduce risk.

5. Overtime Rate

Formula: Overtime Rate = Overtime hours ÷ Regular working hours

Overtime Rate reflects how often labor planning reacts instead of anticipated constraints inside a manufacturing plant.

Where generative AI improves labor and shift planning

- During workforce planning, generative AI aligns labor schedules with demand forecasts that include supplier variability and tool wear.

- Bottlenecks surface earlier in the planning cycle instead of during execution.

- Supervisors adjust staffing during regular shifts rather than relying on weekend overtime.

- This shows how generative AI can help manufacturing teams regain predictability without increasing pressure.

Across these five KPIs, the formulas stay the same. What improves is how decisions are prepared before execution begins inside the manufacturing plant, as outlined in this AI in manufacturing guide. Generative AI strengthens planning and coordination when leadership applies it with clear ownership, discipline, and control.

What Most Manufacturing Plants Underestimate Before Adopting Generative AI

After KPIs come into focus, most manufacturing leaders pause for a reason. The math looks sound, and the use cases feel relevant, yet momentum often slows once implementation begins. The gap rarely comes from the technology itself. Decision behavior, ownership clarity, and workflow discipline determine outcomes once generative AI enters daily operations inside a manufacturing plant.

Decision ownership does not disappear

Generative AI produces recommendations, but accountability remains human. When a model suggests a change, someone must still decide whether that change is executed.

Common breakdowns seen in manufacturing plants include:

- Production teams continue prioritizing output targets while quality risks surface several shifts later.

- Supervisors override model recommendations without a defined escalation or review process.

- Leadership reviews KPI movement after decisions are executed rather than validating decisions beforehand.

Without clear decision ownership, generative AI in manufacturing use cases struggle to deliver consistent results even when insights are accurate.

Data exists, but alignment does not

Most manufacturing plants already generate sufficient data to begin using generative AI. The real challenge is disagreement over which signals should guide decisions.

Alignment issues typically appear when:

- Engineering teams prioritize process parameters while operators rely on live floor conditions.

- Operations teams trust real-time signals while planning teams rely on historical averages.

- Multiple departments use different definitions for the same performance metric.

When generative AI in the manufacturing industry pulls from conflicting inputs, trust in recommendations weakens and adoption slows.

Operators need context, not instructions

Adoption rarely fails because operators resist technology. Adoption fails when guidance arrives without explanation or operational context.

This breakdown often shows up as:

- Parameter adjustments applied without explaining which conditions triggered the change.

- Recommendations that ignore known constraints on the manufacturing floor.

- Experienced operators reverting to manual judgment when model logic feels disconnected.

Generative AI in manufacturing examples succeed when recommendations explain reasoning that aligns with real operating conditions, including upstream dependencies shaped by AI for supply chain decisions.

Integration timing matters more than integration itself

Connecting generative AI to MES, ERP, scheduling, or maintenance systems is achievable in most manufacturing plants. Problems surface when integration sequencing moves faster than operational readiness.

Integration friction typically appears under the following conditions:

- Alerts reach production or maintenance teams before clear response processes are defined.

- Planning outputs update more frequently than execution teams can review and act on them.

- Multiple signals arrive simultaneously without a defined priority or ownership structure.

These integration failures represent one of the most underestimated risks in generative AI in manufacturing use cases, because trust erodes even when the underlying recommendations are sound.

Early KPI movement is not stability

Initial KPI improvements often appear shortly after generative AI deployment. Many manufacturing teams treat early movement as proof of long-term success.

Stability usually breaks down when the following conditions remain unresolved:

- Feedback loops exist but are not yet embedded into daily operating routines.

- Decision behaviors remain unchanged even though new recommendations are available.

- Overrides and exceptions occur but are not consistently reviewed or documented.

Manufacturing leaders who account for this transition phase extract durable value from the benefits of generative AI in manufacturing, rather than temporary performance gains.

Generative AI delivers value in manufacturing plants when leadership treats adoption as an operating decision, not a software exercise. Clear ownership, aligned data priorities, and disciplined execution determine whether early KPI movement becomes repeatable performance.

Is Your Manufacturing Operation Ready for Generative AI

Generative AI in manufacturing delivers results only when operational foundations support daily decision-making. Model quality matters, but readiness determines whether recommendations turn into action on the manufacturing floor. Many teams invest early and struggle later because readiness gaps surface after pilots begin.

Below are the pressure points that separate controlled adoption from stalled execution.

Data trust inside the manufacturing operation

Generative AI in the manufacturing industry depends on data that planners, supervisors, and operators already trust. When teams question demand forecasts, routing accuracy, or maintenance logs, AI recommendations face resistance before execution begins.

Key readiness signals include:

- Production planning data reflects actual constraints observed on the manufacturing floor.

- Quality data links defects to specific machines, tools, and material batches.

- Maintenance history includes timestamps that align with downtime and performance loss.

When data trust exists, generative AI use cases in manufacturing translate into decisions rather than debates.

Decision ownership at the KPI level

Generative AI in manufacturing use cases generates recommendations faster than traditional review cycles. Performance stalls when KPI ownership and decision authority remain unclear, even when insights are available.

Operational readiness exists under the following conditions:

- Each KPI has a named owner with the authority to act on AI-generated recommendations.

- Supervisors know when to follow model output and when to formally document exceptions.

- Leadership reviews focus on decisions executed and operational outcomes, not only reported metrics.

Clear KPI ownership allows the benefits of generative AI in manufacturing to surface inside daily manufacturing operations rather than remaining trapped in analysis.

Workflow alignment between planning and execution

Many generative AI in manufacturing examples fail because planning outputs never reach execution teams in usable form. Readiness requires workflows that carry recommendations from screens into shift-level actions.

Alignment exists when:

- AI-generated schedules integrate directly into existing MES or dispatch tools.

- Setup instructions reflect available tools, fixtures, and staffing conditions.

- Operators receive context, not raw data, during execution.

Aligned workflows answer a common leadership question: how can generative AI help in manufacturing without slowing production.

Risk tolerance and operational pacing

Generative AI in manufacturing adoption moves faster than cultural comfort inside many organizations. Readiness includes clarity on where experimentation is acceptable and where stability remains mandatory.

Healthy pacing shows up when:

- Pilot areas operate with defined guardrails and rollback plans.

- Performance thresholds trigger human review rather than silent overrides.

- Leadership communicates acceptable risk levels to plant and operations teams.

Controlled pacing protects uptime while generative AI expands its operational footprint.

Manufacturing leaders who meet most readiness conditions usually deploy generative AI with fewer disruptions and faster operational impact, especially when initiatives intersect with AI quality control in manufacturing practices. Leaders who uncover gaps gain clarity on what must be corrected before scaling across the manufacturing operation. A focused operational diagnostic often identifies the single readiness gap with the highest cost exposure.

Implementation Paths for Generative AI in Manufacturing

After preparing your data and production systems, the next step is deciding how to apply generative AI in manufacturing. Success depends less on the AI model itself and more on picking an approach that fits your plant’s workflow. Leaders typically focus on three practical implementation paths, each offering distinct benefits and trade-offs.

Path 1: Internal build inside the manufacturing organization

Building a generative AI solution internally gives your organization full control over models, data, and integration. This allows for highly customized solutions tailored to your specific manufacturing workflows and processes.

Key Advantages of Building Generative AI Internally:

- Developing AI internally allows your team to maintain full ownership of the models, ensuring that sensitive manufacturing data stays secure within the organization.

- Internal teams can integrate the AI outputs directly into existing systems like ERP or MES, ensuring seamless interaction with current workflows.

- Continuous internal oversight enables rapid iteration and fine-tuning of the models to meet evolving production requirements.

- The in-house approach builds expertise among your engineers, creating long-term internal capabilities for future AI projects.

Best fit: This approach is ideal for manufacturing companies with experienced data science teams and strict requirements for data security and internal ownership.

Internal builds are most effective when control, customization, and internal expertise are top priorities.

Path 2: Vendor-led generative AI deployment

Engaging a vendor-provided AI solution allows manufacturers to deploy generative AI quickly without heavy internal resources. Pre-built modules address common challenges like production scheduling, quality assurance, and predictive maintenance.

Key Advantages of Using Vendor-Led AI Solutions:

- Vendors offer ready-to-use modules that can be deployed within weeks, providing rapid visibility into AI-driven improvements.

- Access to vendor expertise ensures reliable implementation, ongoing support, and model updates without burdening your internal teams.

- Pre-built solutions reduce the risk of project failure by leveraging workflows validated across multiple manufacturing facilities.

- Organizations can quickly measure ROI and operational impact, helping leadership justify further AI investments.

Best fit: This path works for companies that want to test generative AI’s value quickly and have limited internal AI expertise.

Vendor-led solutions are most suitable for organizations seeking fast deployment and measurable early results without building full internal teams.

Path 3: Phased custom implementation aligned to plant maturity

The hybrid approach combines the speed of vendor solutions with the control of internal development. It starts with a pilot led by a vendor and gradually transitions ownership to internal teams.

Key Advantages of a Phased Hybrid Approach:

- The initial vendor-led pilot provides immediate insights and measurable improvements, demonstrating the practical value of generative AI.

- Knowledge transfer from the vendor to your internal team builds in-house expertise while maintaining project continuity.

- Gradual adoption reduces risk by ensuring internal teams are confident and prepared to manage AI systems independently.

- This approach allows organizations to scale AI implementation across multiple plants while maintaining control over customization and data security.

Best fit: This path is ideal for multi-plant manufacturers seeking a balance between rapid results and long-term independence.

The phased hybrid model ensures a smooth transition from pilot to full-scale implementation while developing internal capabilities.

Each implementation path for generative AI in manufacturing reflects a different balance between control, speed, and operational risk, often shaped by the level of internal expertise versus reliance on AI development services. Manufacturing leaders who match the path to data maturity, internal capability, and governance avoid stalled pilots and fragmented execution.

Real BMW Generative AI in Manufacturing Examples You Should Know

BMW leverages generative AI in manufacturing to optimize design, streamline production, and reduce material waste. From accelerating prototype development to improving quality control and predictive maintenance, BMW’s use of AI ensures faster production cycles, higher efficiency, and significant cost savings while maintaining exceptional product standards.

How BMW Reduced Conveyor Downtime with AI

BMW implemented in-house AI models to monitor conveyor data in real time. The system identifies anomalies like unusual power draw or barcode errors and triggers maintenance alerts, preventing unplanned stoppages. This approach saved 500 minutes per year, preserving assembly output and maintaining vehicles rolling every 57 seconds.

Challenge: Unplanned conveyor stoppages interrupted the assembly line, risking delays in vehicle production.

Solution: In-house AI models analysed real-time data from control units, including power draw, movement patterns, and barcode readability. Any detected anomaly immediately triggered maintenance alerts for proactive intervention.

Audited Result: The system prevented approximately 500 minutes of disruption annually on the main assembly line. With vehicles rolling off every 57 seconds, this directly preserved output and minimized production losses.

How Did BMW Improve Weld-Gun Reliability Using AI?

AI compares each welding gun’s signature to a global database to detect early wear. Alerts appear on plant dashboards, allowing preemptive action. During pilot trials, this reduced tip replacements by 20% and prevented unplanned weld-line stops, ensuring smoother body-shop operations and higher production reliability.

Challenge: Each welding gun performs around 15,000 spot welds daily. Tip wear often caused quality faults and unplanned production stops.

Solution: A cloud-based AI model compares real-time welding signatures against a global library. Alerts were pushed to plant dashboards for early intervention before quality issues occurred.

Audited Result: Pilot trials achieved a 20% reduction in tip replacements and recorded zero unplanned weld-line stoppages during the quarter.

BMW’s use of generative AI in manufacturing shows how advanced analytics can transform operations, often supported by teams that choose to hire AI developers with deep production and data expertise.

The system boosts efficiency, cuts waste, and ensures high-quality production, proving its value as a strategic driver for smarter, faster, and more sustainable automotive manufacturing.

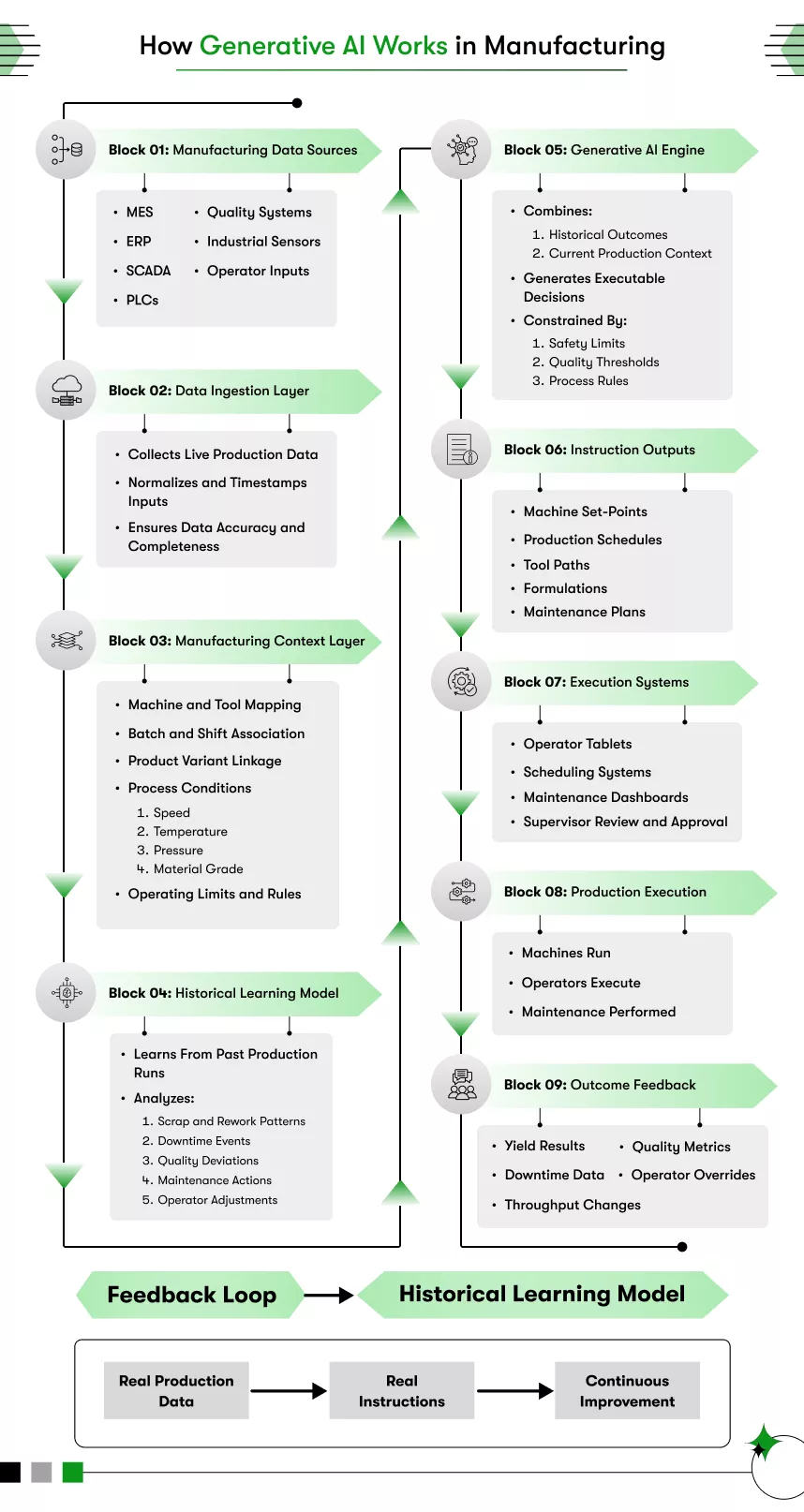

How Generative AI in Manufacturing Works Practically

Generative AI in manufacturing follows an operational flow that connects shop floor data with real production decisions. The impact comes from how manufacturing data moves through systems, becomes instructions, and influences daily execution.

The following flow explains how generative AI operates inside real manufacturing environments.

Step 1: Data is captured from active manufacturing systems

Generative AI in the manufacturing industry begins with data generated during real production activities. The data reflects actual machine behavior, process variation, and operational constraints. Accuracy and relevance determine model reliability.

- Data is collected from MES, ERP, SCADA, PLCs, quality systems, and industrial sensors used on the manufacturing floor.

- The data includes machine parameters, cycle times, defect records, maintenance logs, material specifications, and operator inputs.

- Each data source represents real production conditions inside the manufacturing plant.

Operational production data forms the foundation for all generative AI use cases in manufacturing.

Step 2: Manufacturing context is applied to raw data

Raw production data alone does not explain why outcomes occur. Generative AI applies manufacturing context so relationships between actions and results become visible. Process-level understanding replaces isolated data points.

- Each data point is linked to specific machines, tools, batches, shifts, and product variants used during production.

- Process conditions such as speed, temperature, pressure, tooling state, and material grade are mapped to output results.

- Historical constraints, operating limits, and standard process rules are embedded into the data structure.

Manufacturing context allows generative AI in manufacturing to reflect real cause-and-effect behavior.

Step 3: Models learn from historical production outcomes

Generative AI models learn by analyzing how past production decisions affected performance. The system studies outcomes produced under real operating conditions. Learning remains grounded in manufacturing reality.

- The model analyzes how parameter changes influenced scrap rates, downtime events, and quality deviations.

- Past failures, corrective actions, maintenance interventions, and operator adjustments are included in training.

- Relationships between process inputs and production outcomes are learned over repeated cycles.

Historical learning supports reliable and repeatable generative AI in manufacturing examples.

Step 4: Generative AI produces new manufacturing instructions

Generative AI differs from traditional analytics by creating executable production instructions. The system generates outputs designed for direct use inside manufacturing processes. Decision support becomes operational action.

- The system generates machine set-points, production schedules, tool paths, paint formulations, or maintenance plans.

- Each instruction reflects current production conditions combined with historical performance patterns.

- All outputs remain constrained by defined safety limits, quality thresholds, and process rules.

Instruction generation explains how generative AI can help in manufacturing execution.

Step 5: Instructions are delivered through existing workflows

Generative AI supports production teams without disrupting established operations. Recommendations flow into systems already used by manufacturing staff. Human oversight remains part of execution.

- Generated instructions appear in operator tablets, scheduling systems, or maintenance dashboards already in use.

- Engineers and supervisors review recommendations before applying them to production.

- Existing approval structures and operational controls remain unchanged.

Workflow-level integration enables adoption without operational risk.

Step 6: Production outcomes drive continuous learning

Every executed instruction produces measurable results. Generative AI captures those outcomes and refines future outputs. Learning improves with every production cycle.

- Quality results, downtime events, throughput metrics, and yield changes are recorded automatically.

- Operator adjustments and exceptions are logged and incorporated into model updates.

- Output accuracy improves as feedback accumulates across production runs.

Continuous feedback unlocks sustained benefits of generative AI in manufacturing.

Generative AI in manufacturing works by transforming operational data into executable production decisions inside existing systems. When data quality, process context, and workflow integration align, manufacturing plants achieve consistent improvements in efficiency, quality, and cost control.

Examples of How Generative AI Can Help in Manufacturing

Manufacturing teams use generative models to turn historical production data into instructions that guide machines, schedules, and quality decisions. The impact shows up in fewer trial runs, tighter control, and faster execution across daily operations.

1. Optimizing Machine Set-Points Before Production

Production efficiency depends on how accurately machines are configured at the start of a run, which is one of the most practical generative AI use cases in manufacturing. Models analyze prior production runs to generate starting parameters that reflect real operating conditions.

- The system generates initial machine set-points that account for material variation, tool wear, and environmental conditions.

- Operators begin production closer to specification, which reduces adjustment cycles during ramp-up.

- First-pass yield improves because fewer parts fall outside tolerance at the start of the run.

2. Improving Production Scheduling and Line Balance

Scheduling affects throughput, labor cost, and delivery reliability. Generative models produce schedules that reflect actual shop-floor constraints instead of ideal assumptions.

- The system creates schedules that consider capacity limits, historical changeover time, and machine availability.

- Bottlenecks are identified before execution, allowing supervisors to rebalance workloads in advance.

- On-time delivery improves without adding overtime or additional shifts.

3. Planning Maintenance Around Production Reality

Equipment reliability improves when maintenance timing reflects actual machine behavior, which is one of the key benefits of generative AI in manufacturing. Models learn failure patterns and generate maintenance plans aligned with production needs.

- Maintenance actions are scheduled based on predicted wear rather than fixed calendar intervals.

- Interventions occur during low-impact production windows instead of peak output periods.

- Equipment availability increases because failures are addressed before breakdowns occur.

4. Preventing Quality Issues Earlier in the Process

Quality losses often originate upstream in the process. Generative models detect early signals and adjust parameters before defects appear.

- Process parameters are adjusted based on patterns associated with prior quality deviations.

- Scrap and rework decrease because defects are prevented rather than detected downstream.

- Quality decisions remain traceable for audits and compliance reviews.

5. Reducing Engineering Effort in Tooling and Fixtures

Engineering teams spend time repeating similar design tasks. Generative models reduce this load by producing production-ready designs.

- Tool paths and fixture concepts are generated using part geometry and machining constraints.

- CNC programming time decreases because fewer manual iterations are required.

- Engineering teams focus on process improvement instead of routine design work.

6. Improving Material Usage and Process Formulations

Material cost control and batch consistency depend on how accurately formulations are defined before production starts, which is one of the practical generative AI in manufacturing examples seen in process-driven industries. Generative AI supports formulation decisions by learning from historical material behavior and process outcomes.

- The system analyzes historical batch results, material properties, and process parameters to generate an initial formulation that aligns with target performance specifications.

- Production teams start with a formulation that already reflects prior successes, which reduces the need for trial-and-error adjustments during manufacturing.

- Material waste and reprocessing costs decrease because fewer batches fail to meet quality or performance requirements.

Production data creates value only when it turns into executable shop-floor instructions. Manufacturing teams gain tighter control, faster response, and measurable improvements across quality, uptime, and cost without changing existing systems.

What a 30-Day Generative AI Pilot Looks Like in a Manufacturing Plant

A 30-day pilot exists to answer one question only: does the model move a real manufacturing KPI without disrupting operations. The scope stays narrow, the risk stays controlled, and success is measured using numbers already trusted by leadership.

Week 1: Define the problem and lock one KPI

The pilot starts by selecting a single operational problem that already appears in weekly reports. The goal is to prove impact fast, not to modernize the entire manufacturing plant.

- The team selects one KPI such as scrap rate, changeover time, unplanned downtime, or overtime cost.

- Ownership is assigned to one manufacturing leader who already manages the KPI.

- Success criteria are documented using existing formulas and reporting systems.

A clear KPI target keeps the pilot focused and prevents scope creep.

Week 2: Connect data and build process context

Data connection focuses only on systems that influence the selected KPI. The objective is speed and accuracy, not full data coverage.

- Relevant data is pulled from MES, ERP, quality systems, and machine logs tied to the KPI.

- Process context is added by mapping machines, tools, shifts, and product variants.

- Data quality issues are documented rather than hidden.

Context-ready data allows the model to reflect real manufacturing behavior.

Week 3: Generate and test production instructions

The model begins producing outputs that mirror daily decision-making. Instructions are reviewed before execution to maintain operational control.

- The system generates machine parameters, schedules, or maintenance actions tied to the KPI.

- Engineers and supervisors review recommendations before applying them.

- Results are tracked using the same reports leadership already trusts.

Early results show whether generative AI use cases in manufacturing translate into action.

Week 4: Measure results and decide next steps

The final week focuses on measurement, not expansion. Leadership evaluates performance using actual production outcomes.

- KPI movement is compared against the pre-pilot baseline.

- Operational effort and disruption are assessed honestly.

- A go, pause, or scale decision is made using documented results.

Clear outcomes replace assumptions and guide informed investment decisions.

A 30-day pilot proves whether generative AI in manufacturing creates value inside real workflows. When the pilot moves one KPI with minimal disruption, manufacturing teams gain confidence to scale with control, not risk.

Conclusion

Generative AI in manufacturing is actively improving uptime, quality, material efficiency, and decision speed inside live production environments. Manufacturers that act early gain stronger process control, fewer operational disruptions, and more predictable costs without changing existing systems.

Real advantage comes from applying generative AI directly to shop-floor data, operational constraints, and business priorities, rather than treating it as a disconnected technology initiative.

The fastest path forward is action, not debate. A focused pilot reveals where value appears, what effort is required, and how teams adapt. From that point, scaling becomes a business decision backed by data, not assumptions.

Kody Technolab helps manufacturing companies implement generative AI with execution discipline, bringing the experience expected from a generative AI development company into real production environments. The team connects models to MES, ERP, and production systems, designs KPI-driven pilots, and builds scalable solutions aligned with operational realities. The result is faster adoption, controlled risk, and production-ready outcomes leadership can trust.

Frequently Asked Questions on Generative AI in Manufacturing

1. Where does generative AI create value first in a manufacturing plant?

Generative AI delivers value fastest in areas where decisions repeat daily and variability causes loss. Common starting points include scrap reduction, changeover optimization, unplanned downtime, and overtime control. These areas already have data and clear KPIs, which allows results to appear without changing core systems.

2. Do manufacturing plants need clean or perfect data before starting?

Perfect data is not required to start. Generative AI works with existing production data as long as the data is traceable to machines, batches, and outcomes. Most pilots begin with imperfect data and improve quality as part of the process. Waiting for ideal data often delays value unnecessarily.

3. How is generative AI different from traditional analytics or dashboards?

Traditional analytics explain what happened after the fact. Generative AI produces forward-looking instructions such as machine settings, schedules, or maintenance actions before issues occur. The value comes from generating executable decisions, not reports that still require manual interpretation.

4. Will generative AI replace operators, planners, or engineers?

Generative AI supports decision-making but does not replace manufacturing roles. Operators, planners, and engineers remain responsible for approval and execution. The system reduces guesswork and manual analysis, allowing teams to focus on higher-value work and exception handling.

5. How risky is deploying generative AI in live production?

Risk is controlled by limiting scope. Pilots target one KPI, one workflow, and one production area. Recommendations are reviewed by teams before execution. This approach ensures AI supports decisions without taking control away from operations.

6. What systems does generative AI need to integrate with?

Most implementations integrate with existing MES, ERP, quality systems, and machine data sources. No rip-and-replace is required. The focus is on connecting AI outputs to systems teams already use.

7. How does leadership measure success objectively?

Success is measured using the same KPI formulas already reviewed in weekly or monthly meetings. Baselines are set before the pilot begins, and performance is compared using real production outcomes, not projected gains.

8. How can Kody Technolab help with generative AI in manufacturing?

Kody Technolab helps manufacturing companies design, pilot, and scale generative AI with execution discipline. The team connects AI models to MES and ERP systems, scopes KPI-driven pilots, and delivers production-ready solutions aligned with real manufacturing constraints.

Contact Information

Contact Information