Quick Summary: Most computer vision project ideas fail because teams chase technology without first defining measurable improvements. This guide explains which projects deliver the fastest ROI and are leading, how to evaluate readiness, and what risks kill deployments. You learn to separate high-return applications from expensive experiments that consume budgets without solving actual operational pain.

Manual inspection cannot keep pace with the visual data your operations generate every hour. Inspectors check 50 units while production outputs 500. Security teams review footage after incidents already happened. Quality problems reach customers because human attention has limits that production speeds cannot accommodate.

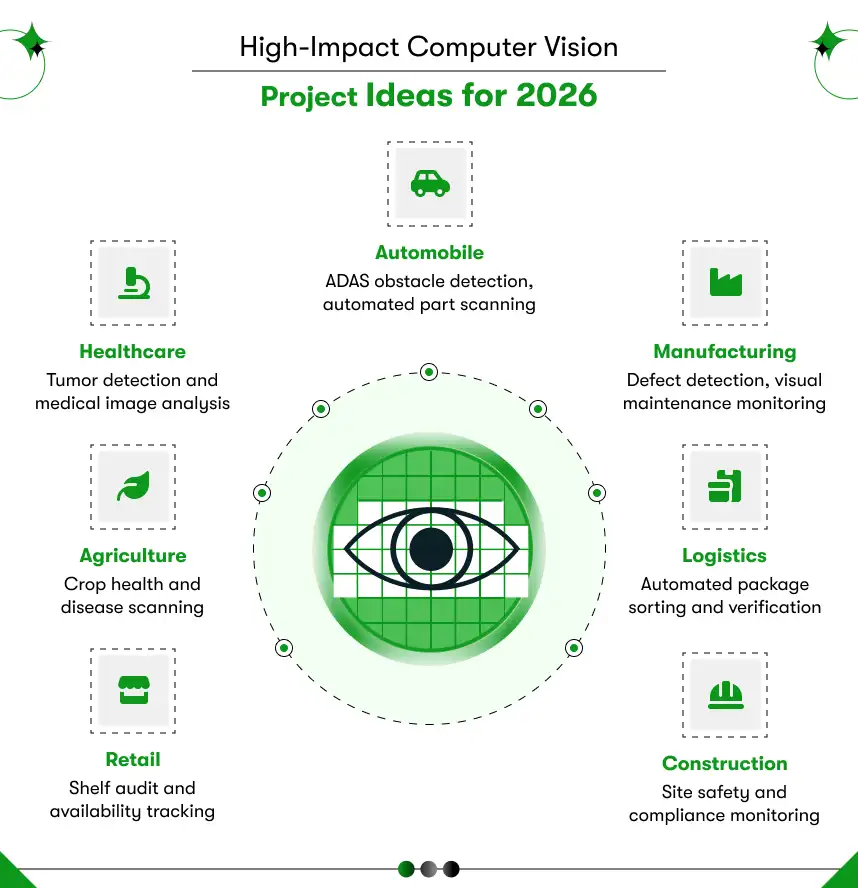

Computer Vision Project Ideas shift from experimental pilots to core systems in 2026 because competitive pressure demands faster decisions and zero-defect tolerance. Leaders ask different questions now: not “Can this work?” but “Which projects pay back fastest and solve actual operational pain?”

Success belongs to organizations that match visual intelligence to measurable business constraints rather than chasing technology trends. Understanding how computer vision works helps executives separate high-return deployments from expensive distractions that deliver visibility without value.

How should leaders choose the right computer vision projects?

Leaders should prioritize computer vision projects based on the severity of operational pain, data availability, integration readiness, and measurable ROI. Projects that replace manual inspection or prevent costly errors deliver value fastest.

Choosing the right Computer vision project ideas separates strategic deployments from expensive experiments that consume budgets without delivering operational improvements. Executives face dozens of potential applications across quality control, safety monitoring, inventory management, and process optimization. Not all projects justify investment despite appearing technically feasible during vendor demonstrations.

Priority decisions require evaluating whether visual automation addresses real constraints that limit business performance or simply adds technology complexity without measurable returns. Projects succeed when they solve problems that cost more than prevention investments and when visual data of sufficient quality already exists for model training.

Business Impact

Clear evaluation criteria prevent wasted spending on projects lacking operational urgency or technical readiness for deployment. Organizations avoid pilot failures by assessing data quality, integration requirements, and accuracy expectations before committing development resources. Understanding Computer Vision Applications and Examples across similar industries helps leaders identify which workflows justify investment based on proven deployment patterns.

Visual data readiness determines whether projects can begin model training immediately or require months of collecting labeled datasets. Existing camera infrastructure, lighting consistency, and image quality directly affect development timelines and the potential for accuracy. Projects fail when organizations discover insufficient training data only after signing development contracts.

Deployment complexity affects the timeline and total cost due to integration requirements with existing enterprise systems, such as ERP and MES platforms. Legacy systems lacking modern APIs require custom middleware development that extends implementation schedules. Edge versus cloud architecture decisions impact infrastructure spending and ongoing operational costs.

Time-to-ROI varies significantly across advanced computer vision project ideas, depending on problem complexity and organizational readiness. Quality inspection, preventing recalls, delivering returns within months, while behavioral analytics projects require longer validation periods. Leaders prioritizing faster payback focus on workflows where error costs clearly exceed the cost of automation.

Understanding Computer Vision for Industries helps executives benchmark realistic timelines and expected returns against comparable deployments in similar operational contexts. Organizations exploring Computer Vision Software Development Cost benefit from evaluating multiple project options before committing to specific implementations.

Top 5 Computer Vision Project Ideas for 2026

1) Tumor Detection and Medical Image Analysis

Project Name

AI-Powered Medical Imaging Diagnostic System

Project Description

An automated system analyzes MRI scans, CT images, and X-rays to detect tumors and abnormalities. The system identifies lung nodules in chest scans and spots brain aneurysms before symptoms appear. Radiologists receive flagged abnormalities with attached confidence scores to support faster clinical decision-making in patient cases.

Imaging departments face two critical bottlenecks that slow down patient care across healthcare facilities. Thousands of scans arrive weekly, while qualified experts remain limited in number at most hospitals. Research shows AI concurrent assistance reduces reading time by 27.20% in medical imaging workflows.

Project Technology Used

Convolutional Neural Networks segment medical images and enable accurate analysis across different imaging modality types. Deep learning models are trained on diverse patient populations and varied imaging equipment to achieve robust performance.

Edge computing devices process images locally, reducing latency and avoiding cloud delays. Integration APIs connect with existing PACS, EMR, and RIS platforms at healthcare facilities nationwide. Advanced systems achieved 94% sensitivity at 90% specificity in cancer detection validation studies.

Project Scope

Healthcare organizations deploy computer vision across oncology screening, emergency radiology, and neurological assessment departments. The system detects lung, breast, and brain tumors at earlier stages, when treatment is more effective.

Emergency departments screen chest X-rays for pneumonia in under ten seconds for urgent cases. Brain scans get analyzed for stroke indicators, aneurysms, and degenerative disease markers automatically. Pathology teams reduce Gleason grading time by 21.94% for prostate biopsy analysis workflows.

Business Impact

Radiology departments process more cases daily without hiring additional staff or significantly expanding equipment capacity. Using AI as a second reader reduced reading volume by 44.47% in diagnostic workflows. Identification time for gastric cancer lesions dropped by 99.43% with AI-assisted diagnostic systems. Emergency departments triage patients during critical windows without delays that compromise urgent care outcomes. Organizations measure ROI through lower per-scan costs, higher throughput, and earlier disease detection rates.

Benefits

Computer systems maintain consistent analysis standards without fatigue-related mistakes during extended hospital shifts across departments. Healthcare facilities process more scans daily without expanding radiology staff or purchasing additional imaging equipment.

Early detection identifies conditions at stages when treatment delivers optimal outcomes for patient recovery. Systems operate continuously without breaks, weekends, or holidays, affecting diagnostic capability for urgent cases.

Expert physicians focus on complex cases requiring specialized judgment rather than routine screening tasks. Rural hospitals gain access to expert-level diagnostic analysis without hiring full-time specialists.

2) Automated Part Scanning

Project Name

AI-Powered Manufacturing Quality Inspection System for Automotive Components

Project Description

An automated inspection system simultaneously examines automotive components for surface defects, dimensional accuracy, and assembly errors. The system detects scratches, dents, paint quality issues, and part misalignment at production line speeds. Production lines generate millions of components requiring inspection before assembly begins on vehicle manufacturing floors.

Manual quality checks consume significant time and often miss defects that camera systems capture with superior accuracy. Automotive surface inspection achieved 95.6% accuracy for dent detection and 97.1% for scratch detection. Machine vision improves defect detection by up to 90%, achieving 95.6% accuracy in assembly line applications.

Project Technology Used

Convolutional Neural Networks trained on production imagery automatically distinguish true defects from acceptable manufacturing variations. Support Vector Machines combine with deep learning models for robust classification across different component types.

High-resolution industrial cameras capture detailed images as products move through production lines at operational speeds. Advanced lighting configurations reduce specular reflection from painted surfaces, thereby obscuring defect visibility during inspection. Edge computing devices process images locally, reducing latency without relying on cloud infrastructure.

Project Scope

Manufacturers integrate computer vision at stamping operations, assembly verification, and final inspection stages throughout production. Metal surface inspection catches scratches, dents, and corrosion before parts reach expensive downstream processing steps.

Paint quality assessment identifies orange peel texture, drips, and color inconsistencies on finished vehicle surfaces. Weld inspection detects voids, porosity, and lack of fusion in critical structural joints using imaging. Assembly verification ensures correct part placement, proper alignment, and appropriate torque application during vehicle assembly.

Business Impact

Defect detection in early production stages prevents value-added processing of flawed components, which would otherwise require rework. Manufacturers measure substantial savings when computer vision prevents defective products from reaching customers after delivery. One major consumer goods manufacturer projected $500 million in annual savings from implementing defect detection.

Automotive recalls cost significantly more when safety issues emerge after customer delivery and media coverage. Quality standards remain consistent, with no subjective judgment variation among human inspectors across manufacturing shifts.

Benefits

Production teams identify root causes faster by analyzing detailed defect patterns over time with statistical tracking. Consistent inspection eliminates subjective variations that occur when different human inspectors evaluate identical components under pressure.

Systems operate continuously across multiple shifts without performance degradation from fatigue or distraction, and without accuracy being affected. Real-time monitoring enables instant alerts when defect rates exceed thresholds that require immediate intervention.

Statistical process control benefits from pixel-level defect masks that track quality issues across production batches. Organizations implementing computer vision projects should prioritize applications where accuracy consistently exceeds the human baseline.

3) Defect Detection Systems

Project Name

AI-Powered Production Line Quality Inspection System

Project Description

An automated visual inspection system analyzes manufactured components for surface defects during high-speed production runs. The system identifies scratches, dents, cracks, and dimensional variations before defective parts enter assembly processes. Production environments generate constant visual data that manual inspection teams cannot process without introducing errors. Traditional rule-based inspection systems plateau at limited accuracy because rigid programming cannot adapt to variations. Machine learning inspection achieves over 60% accuracy increases compared to traditional methods in manufacturing environments. Computer vision systems detect defects with over 99% accuracy while significantly reducing false positives.

Project Technology Used

Convolutional Neural Networks trained on production imagery learn to distinguish genuine defects from acceptable variations. YOLO11 algorithms enable real-time defect detection and instance segmentation in a single forward pass. High-resolution industrial cameras capture detailed images of components as products move through production lines at operational speeds. Advanced lighting systems eliminate reflections and shadows that obscure surface defects from the camera’s view. Edge computing hardware processes images locally, without the cloud latency that would slow production-line throughput.

Project Scope

Manufacturers deploy computer vision across stamping operations, welding inspection, paint quality assessment, and final assembly verification. Surface inspection catches scratches, dents, corrosion, and texture inconsistencies on metal and plastic components. Dimensional measurement verifies that parts meet tolerance specifications before expensive downstream processing begins. Weld quality inspection detects voids, porosity, and fusion problems in structural joints using visual analysis. Assembly verification confirms correct part placement, proper alignment, and appropriate fastener torque during vehicle construction.

Business Impact

Defect detection in early production stages prevents processing of flawed components, which would require expensive rework. One major manufacturer projected $500 million in annual savings from implementing computer vision defect detection. Intel reports $2 million in annual savings from AI vision inspection systems for scrap avoidance alone. Most manufacturers achieve ROI within six months by reducing scrap, returns, and manual costs.

Benefits

Consistent quality standards eliminate subjective variation among human inspectors evaluating identical parts under pressure. Real-time monitoring enables instant alerts when defect rates exceed threshold limits, requiring immediate intervention by teams.

Production teams identify root causes faster through detailed defect pattern analysis tracked statistically over time. Systems operate continuously across multiple shifts without performance degradation from fatigue affecting detection accuracy rates.

Companies report 20% improvement in overall equipment effectiveness and 35% reduction in quality-related defects. Statistical process control benefits from pixel-level defect masks that track quality issues across batches.

4) Visual-Based Maintenance Monitoring

Project Name

AI-Powered Predictive Maintenance Visual Monitoring System

Project Description

A continuous monitoring system analyzes equipment visual data to detect early signs of wear before failures occur. The system identifies surface cracks, abnormal vibrations, fluid leaks, and temperature anomalies on critical machinery components. Traditional maintenance approaches rely on reactive methods or periodic inspections that miss critical warning signs. Equipment failures during production runs cause unplanned downtime, disrupting manufacturing schedules and customer delivery commitments. Vision AI for predictive maintenance captures ten times more information than traditional sensor methods. Industries adopting these systems report 20% improvement in equipment effectiveness and 25% decrease in inventory.

Project Technology Used

Convolutional Neural Networks analyze equipment images to detect subtle anomalies like surface cracks and corrosion. Semantic segmentation techniques identify and localize wear areas with pixel-level accuracy for precise assessment. Thermal imaging cameras detect abnormal heat signatures indicating friction, electrical issues, or fluid circulation problems. Standard cameras monitor machinery movement patterns and flag unusual behaviors, indicating potential malfunctions developing. Edge computing devices process visual data locally for immediate alerts without cloud infrastructure dependency delays.

Project Scope

Manufacturing facilities deploy predictive maintenance across robotic arms, conveyor belts, assembly equipment, and critical production machinery. Wear assessment monitors components like gears, belts, and bearings for degradation patterns over operational time. Vibration analysis through visual data identifies misalignment, imbalance, or bearing failures developing in rotating equipment. Leak detection systems spot fluid issues from hydraulics, coolant systems, and lubrication that indicate seal failures. Equipment operators receive real-time visual data access from anywhere with internet connectivity for remote monitoring.

Business Impact

Predictive maintenance reduces downtime by up to 30% and increases equipment efficiency by 20% consistently. Companies like General Motors and Frito-Lay achieve remarkable operational results using predictive visual maintenance systems. Manufacturing productivity increases by 42% while significantly reducing machine-related downtime through AI-powered vision systems.

Benefits

Maintenance teams identify equipment at greatest risk of failure and respond with targeted interventions before breakdowns. Proactive scheduling enables maintenance during non-peak hours to minimize disruptions affecting production output and deliveries. Organizations plan asset replacement timing better and delay capital expenditures through extended equipment operational life.

Remote monitoring reduces the need for on-site physical inspections in hazardous environments that risk worker safety. Defect rates decrease by 15% while ensuring higher-quality outputs from production lines across facilities. Continuous operation enables the detection of gradual wear invisible to human inspectors during periodic manual checks. Organizations exploring advanced computer vision project ideas should focus on maintenance applications with clear ROI metrics.

5) Defect Detection Systems

Project Name

AI-Powered Production Line Quality Inspection System

Project Description

An automated visual inspection system analyzes manufactured components for surface defects during high-speed production runs. The system identifies scratches, dents, cracks, and dimensional variations before defective parts enter assembly processes. Production environments generate constant visual data that manual inspection teams cannot process without introducing errors. Traditional rule-based inspection systems plateau at limited accuracy because rigid programming cannot adapt to variations. Machine learning inspection achieves over 60% accuracy increases compared to traditional methods in manufacturing environments. Computer vision systems detect defects with over 99% accuracy while reducing false positives significantly.

Project Technology Used

Convolutional Neural Networks trained on production imagery learn to distinguish genuine defects from acceptable variations. YOLO11 algorithms enable real-time defect detection and instance segmentation in a single forward pass. High-resolution industrial cameras capture detailed component images as products move through lines at operational speeds. Advanced lighting systems eliminate reflections and shadows that obscure surface defects from camera visibility. Edge computing hardware processes images locally without cloud latency that would slow production line throughput.

Project Scope

Manufacturers deploy computer vision across stamping operations, welding inspection, paint quality assessment, and final assembly verification. Surface inspection catches scratches, dents, corrosion, and texture inconsistencies on metal and plastic components. Dimensional measurement verifies parts meet tolerance specifications before expensive downstream processing begins on them. Weld quality inspection detects voids, porosity, and fusion problems in structural joints using visual analysis. Assembly verification confirms correct part placement, proper alignment, and appropriate fastener torque during vehicle construction.

Business Impact

Defect detection at early production stages prevents processing on flawed components that would require expensive rework. One major manufacturer projected $500 million in annual savings from implementing computer vision defect detection. Intel reports $2 million annual savings through AI vision inspection systems in scrap avoidance alone. Most manufacturers achieve ROI within six months through reduced scrap, fewer returns, and decreased manual costs.

Benefits

Consistent quality standards eliminate subjective variations between different human inspectors evaluating identical parts under pressure. Real-time monitoring enables instant alerts when defect rates exceed threshold limits, requiring immediate intervention from teams. Production teams identify root causes faster through detailed defect pattern analysis tracked statistically over time. Systems operate continuously across multiple shifts without performance degradation from fatigue affecting detection accuracy rates. Companies report 20% improvement in overall equipment effectiveness and 35% reduction in quality-related defects. Statistical process control benefits from pixel-level defect masks that track quality issues across batches.

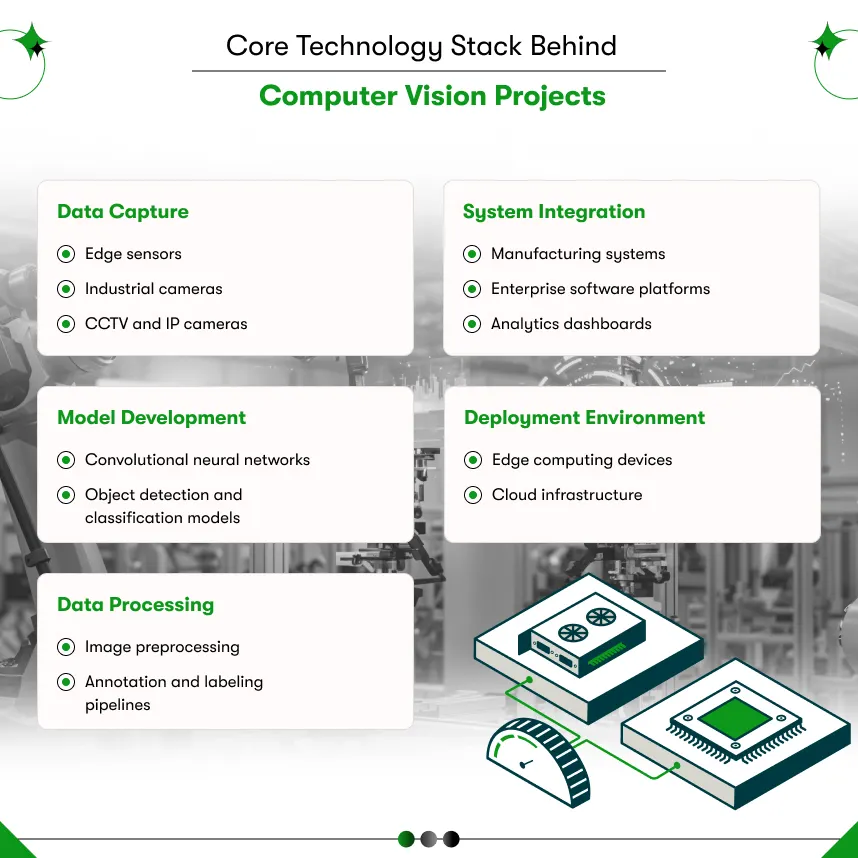

Technology Considerations Behind These Projects

Successful Computer Vision Project Ideas require more than algorithmic capability because production deployments face constraints that laboratory testing never reveals. Organizations underestimate infrastructure requirements, data management complexity, and integration effort needed to move from proof-of-concept demonstrations to systems processing thousands of daily decisions reliably.

Camera and sensor infrastructure – Industrial cameras differ significantly from consumer devices in resolution, frame rates, and environmental durability requirements. Quality inspection requires cameras capturing micro-defects while maintaining consistent performance across temperature variations and vibration exposure. Lighting control becomes critical because shadows and glare affect detection accuracy more than algorithm sophistication. Facilities discover existing installations lack specifications for production deployment, only after pilot testing reveals inconsistent image quality.

Data labeling and quality management – Training accurate models demands thousands of labeled images showing defects and edge cases that human experts must identify consistently. Organizations rarely possess clean datasets because historical inspection relied on subjective judgment without systematic documentation. Creating training sets requires subject matter experts spending weeks reviewing images and applying labels that algorithms use for pattern recognition. Data quality directly determines model performance because algorithms learn only what labeled examples demonstrate during training cycles.

Model training and validation – Initial models trained on limited datasets perform differently under actual production conditions than controlled testing environments suggest. Pilot deployments reveal lighting variations, product positioning inconsistencies, and defect types missing from training sets that reduce real-world accuracy. Validation testing must include edge cases and worst-case scenarios before production deployment to prevent operational failures. Computer Vision Development guide documentation helps teams structure iterative refinement cycles, improving performance through continuous production feedback.

Edge versus cloud deployment – Latency-sensitive applications like production line inspection require edge processing, analyzing images locally without internet dependency, affecting decision speed. Cloud deployments suit batch processing and centralized analytics, but create risks when network failures halt time-critical operations. Hybrid architectures balance real-time edge decisions with cloud-based model updates and performance monitoring across distributed locations. Infrastructure costs vary dramatically between deployment approaches, affecting total project budgets and ongoing operational expenses.

Enterprise system integration – Vision outputs must trigger actions in manufacturing execution systems and warehouse management platforms without manual data transfer, creating delays. Legacy systems lacking modern APIs require custom middleware development that extends timelines and increases maintenance complexity significantly. Integration testing validates vision decisions flow correctly through downstream processes before production cutover to prevent workflow disruptions. Organizations exploring Computer Vision Tools and library benefit from understanding which frameworks support existing enterprise platforms versus requiring complete infrastructure replacement.

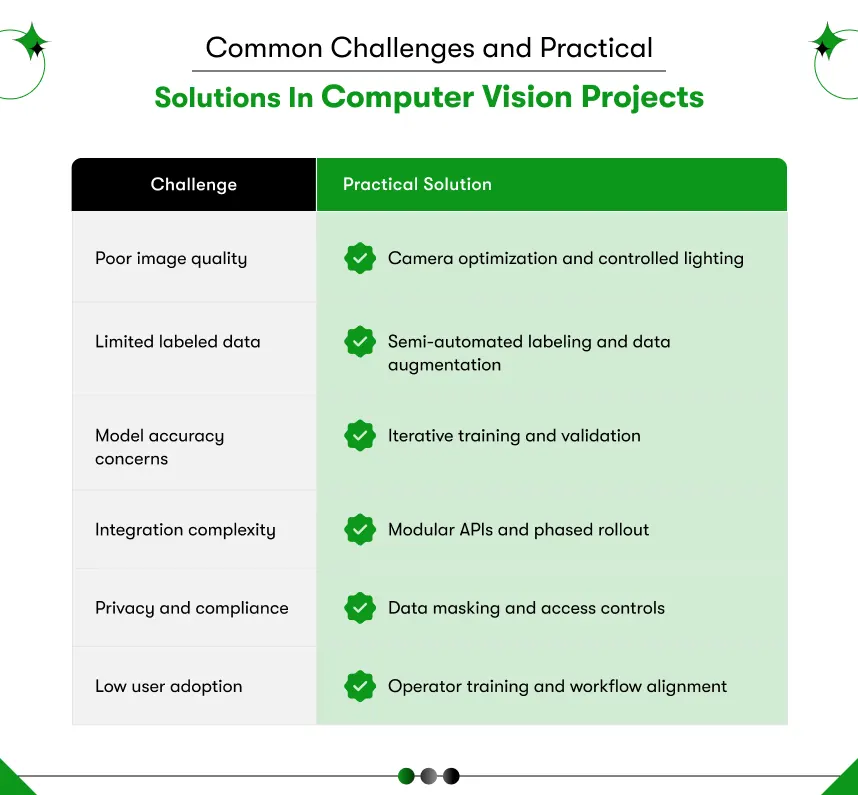

Common Risks Leaders Should Anticipate

Computer Vision Project Ideas fail more often due to overlooked operational realities than to technical limitations in algorithms or hardware capabilities. Organizations allocate budgets based on vendor demonstrations that show perfect accuracy under controlled conditions, without stress-testing assumptions against the messy realities of production environments.

Data quality limitations – Existing cameras capture images optimized for security monitoring rather than defect detection, requiring different specifications. Inconsistent lighting across shifts creates detection variability that algorithms cannot overcome without controlled illumination infrastructure. Product positioning variations introduce angles that training datasets never covered during model development. Organizations discover data inadequacy only after spending months on model training that fails to meet accuracy targets.

Accuracy expectations – Executives assume computer vision achieves human-level performance immediately, without understandingthat initial deployments require iterative refinement cycles. False positive rates halting production lines create operations team after repeated unnecessary stops. False negatives allowing defects through undermine investment justification when quality problems still reach customers despite automation deployment.

Integration challenges – Legacy systems lack APIs accepting real-time vision inputs without custom middleware development, extending timelines beyond estimates. Network latency between edge devices and central systems introduces delays affecting time-sensitive decisions. IT departments resist architecture changes, introducing new failure points into stable operational technology environments.

Privacy and regulatory constraints – Facial recognition faces legal restrictions varying across jurisdictions and employee privacy protections affecting deployment scope. Medical imaging applications require HIPAA compliance, affecting data storage and transmission throughout the system architecture. Manufacturing facilities operating globally must navigate different data residency requirements affecting cloud deployment options.

Workforce adoption – Production teams resist automation, perceived as threatening job security rather than eliminating tedious tasks. Operators distrust algorithmic decisions without understanding the model logic affecting judgment calls. Training gaps leave staff unable to handle exception cases requiring human confirmation. Organizations exploring computer vision consulting benefit from partners experienced in navigating workforce transitions alongside technical implementations.

Conclusion

Top Computer Vision Project Ideas succeed when organizations tie deployments directly to operational pain, causing measurable financial impact through quality failures or throughput limitations. Projects fail when teams chase technology trends without defining specific improvements in scrap reduction percentages, inspection speed increases, or error rate decreases before development begins. Industry-specific applications deliver faster ROI because domain constraints shape realistic accuracy targets matching actual production conditions rather than laboratory demonstrations.

Successful computer vision examples across industries demonstrate how planning rigor and partner capability decide performance outcomes more than algorithm selection alone, because implementation challenges emerge during production deployment rather than controlled testing phases. Organizations ready to scale often need to hire computer vision developers with production deployment experience who understand industrial requirements versus laboratory demonstrations.

Kody Technolab Limited supports organizations through custom computer vision software development grounded in operational reality across messy production environments where reliability matters more than feature demonstrations. As a computer vision software development company, the team guides problem definition, technology architecture selection, pilot validation planning, and enterprise system integration for production deployments requiring consistent performance across shifts and facilities. Organizations seeking predictable outcomes through measurable business impact can engage Kody Technolab Limited as a long-term development partner.

FAQ

What makes certain computer vision project ideas succeed faster than others?

Projects that fix expensive problems right now pay back fastest. Quality defect detection, catching recalls before they happen, shows returns in months because one prevented recall covers years of system costs. Computer Vision Project Ideas focused on safety monitoring or inspection bottlenecks deliver measurable value, while experimental behavioral tracking takes forever, proving no one cares.

How much does implementing computer vision project ideas typically cost for manufacturing facilities?

Pilot testing on one production line runs covering cameras, computers, programming, and hooking everything together. It might cost less or more depending on your requirement. Full factory rollouts cost more, but most places get their money back within a year through less scrap and fewer customer complaints. Small ideas for computer vision projects targeting single inspection points cost significantly less while still solving real operational pain.

Which industries show the fastest adoption of computer vision project ideas in 2026?

Manufacturing plants, hospitals, warehouses, and farms lead because visual mistakes cost serious money through recalls, misdiagnoses, wrong shipments, or crop losses. Computer vision project ideas 2026 gain traction in sectors facing regulation and liability pressure, making investment decisions easier when you can point at specific risks automation prevents.

How long does deploying Top Computer Vision Project Ideas take from planning to production?

Testing one application takes four to seven months from kickoff to live operation, including all the data work, training, testing, and integration. Top Computer Vision Project Ideas rolling out across multiple locations add another year because each site has quirks requiring adjustment even after the first one works perfectly.

What separates successful implementations from failed pilot projects?

Winners match technology to actual messy conditions instead of perfect demo environments. Failed Computer Vision Project Ideas skip boring work like setting accuracy targets, checking image quality, or planning how vision outputs trigger actions in existing systems before spending money on development.

How do organizations measure ROI on computer vision project ideas after deployment?

Write down your current scrap percentage, inspection hours, and customer return rate before starting anything. Check those same numbers six months after going live to see actual improvement from Computer Vision Project Ideas rather than trusting vendor promises about what should happen in perfect laboratory conditions.

Can computer vision project ideas handle product variety in custom manufacturing environments?

Anomaly detection works better for custom shops because systems learn what normal looks like instead of memorizing every defect across every variant. Computer Vision Project Ideas using this approach succeed when defining acceptable appearance proves easier than cataloging everything that could go wrong across limited training examples per unique part.

Contact Information

Contact Information