Route optimization using predictive analytics has become essential in modern logistics. Businesses now rely on it to manage complexity, reduce costs, and meet growing delivery demands.

As delivery networks expand and customer expectations rise, businesses must leverage data-driven strategies to stay competitive. Predictive analytics for delivery route optimization enables companies to anticipate potential disruptions, optimize routes in real-time, and enhance overall efficiency.

A testament to route optimization growing importance, the global route optimization software market is projected to grow from $7.75 billion in 2024 to $8.86 billion in 2025, reflecting a 14.3% compound annual growth rate (CAGR). (Source: the business research company)

This surge underscores the increasing reliance on advanced analytics to streamline delivery operations.

In this blog, we’ll delve into how predictive analytics transforms route planning, reduces operational costs, and improves customer satisfaction. Understanding the applications and benefits of predictive analytics helps businesses navigate complex logistics more effectively.

What Is Route Optimization Using Predictive Analytics?

Route optimization using predictive analytics refers to the use of real-time and historical data to determine the most efficient delivery routes. Instead of relying on static maps or fixed schedules, predictive models evaluate variables like traffic patterns, weather changes, order density, and vehicle performance to generate smarter route plans.

Predictive route planning creates delivery paths that are not just shorter, but also more responsive to external factors. Powered by predictive analytics in delivery, optimized routing algorithms account for live traffic, avoid bottlenecks, and consider recipient availability. This process improves route optimization in delivery while reducing manual adjustments for dispatchers.

Logistics platforms powered by predictive analytics for route optimization evaluate patterns and forecast route disruptions before they occur. For example, if a specific area consistently slows down during certain hours, the platform will proactively assign an alternate route.

As a result, companies experience more flexible and efficient route optimization in delivery services. These improvements are further enhanced by AI for delivery route planning, which continuously refines delivery paths to support predictive delivery optimization across time-sensitive operations.

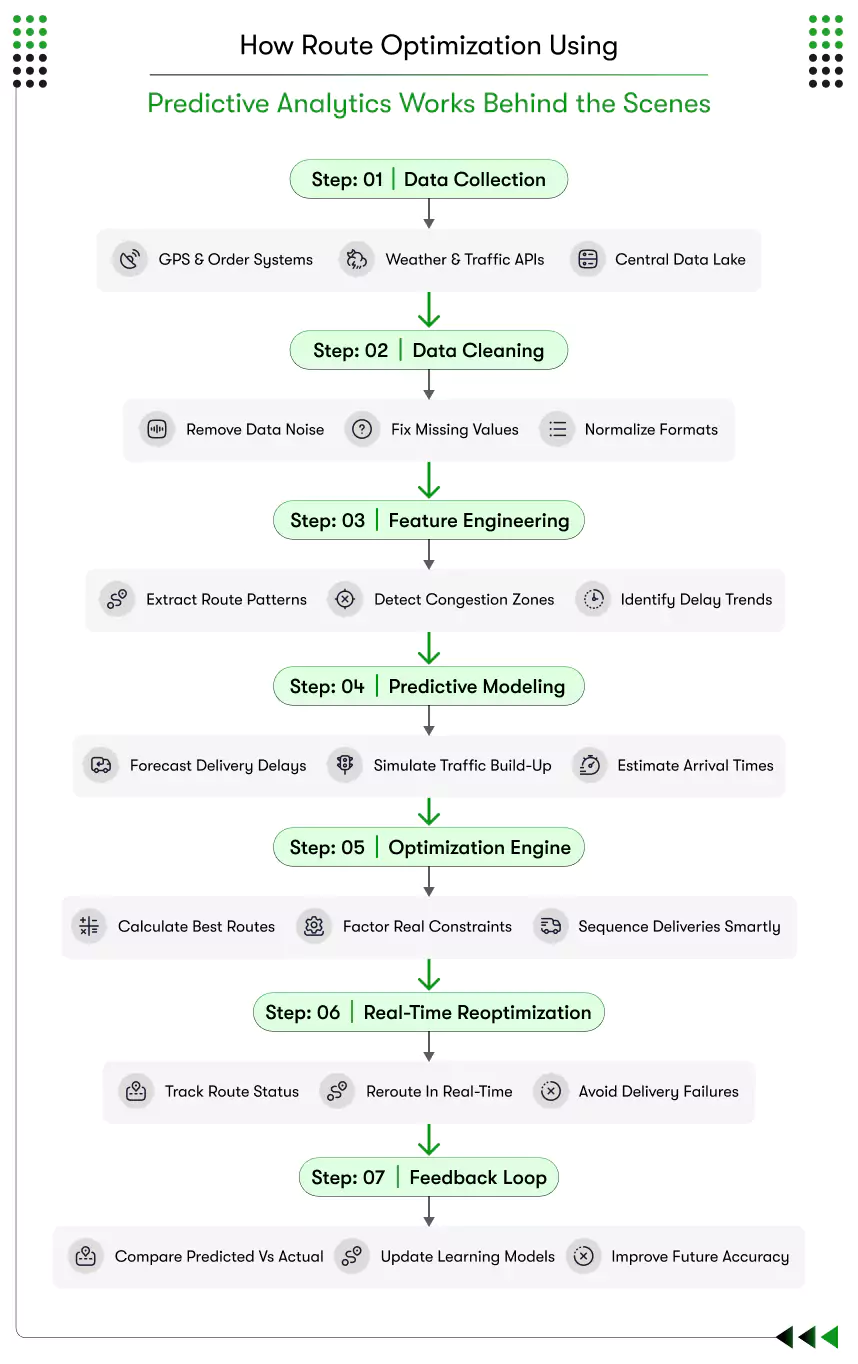

How Route Optimization Using Predictive Analytics Works Behind the Scenes

Route optimization using predictive analytics relies on a multi-layered backend system that transforms raw delivery data into smarter, faster routing decisions. Below is the process explained step by step:

Step-1: Data Collection from Delivery Ecosystems

- The process starts by connecting systems like GPS trackers, order management software, weather feeds, and traffic APIs.

- These integrations feed real-time and historical data into a centralized cloud-based data lake.

- This stage is foundational for all predictive tasks in route optimization in delivery.

Step–2: Data Cleaning and Structuring

- Incoming data is often incomplete or inconsistent, so it passes through automated data pipelines.

- These pipelines normalize formats such as timestamps and geolocation, remove noise, and handle missing values.

- Cleaned data ensures accuracy in the next stages of predictive analytics for route optimization.

Step–3: Feature Engineering and Pattern Recognition

- The system extracts useful features like delivery delays per region, road congestion times, and average dwell times.

- These features allow pattern-detection models to identify repetitive issues in specific routes or time windows.

- This insight forms the foundation for smarter route optimization in delivery services.

Step–4: Predictive Modeling and Forecasting

- Predictive models such as regression, time-series, or decision trees simulate future delivery conditions, aiding demand forecasting for delivery services.

- These models forecast potential delays, traffic build-up, and estimated drop-off times.

- This predictive layer supports AI for delivery route planning by identifying risks before they cause delays.

Step–5: Route Optimization Engine Activation

- Once forecasts are ready, the system runs an optimization engine to find the best delivery sequence.

- Constraints like time windows, fuel limits, driver schedules, customer priority levels, and customer behavior prediction for food recommendations are all factored in.

- This is where predictive delivery optimization replaces guesswork with data-backed routing.

Step–6: Real-Time Reoptimization During Delivery

- As deliveries begin, the system tracks active routes and monitors conditions through driver apps and IoT sensors.

- If there is a delay, roadblock, or cancellation, the system reprocesses the route instantly.

- This dynamic rerouting is powered by predictive analytics for delivery route optimization.

Step–7: Performance Feedback and Model Retraining

- After completion, the system compares actual delivery metrics with predicted ones.

- Gaps between forecast and reality are used to retrain the models for better accuracy in the next cycle.

- This feedback loop is what keeps improving route optimization using predictive analytics over time.

Each layer in the backend process works together to make delivery routes smarter, faster, and more reliable. Businesses that adopt route optimization using predictive analytics gain the ability to respond to changing conditions with precision and confidence.

How Real-Time Data Streams Are the Backbone of Predictive Routing

Predictive analytics for delivery route optimization works only as well as the data it receives. Without the live and accurate inputs, even the smartest AI models cannot prevent the delays. That’s why all the predictive systems rely on continuous streams of real-time data to drive every decision.

Let’s explore the key data sources powering modern route optimisation in delivery services:

Live Traffic Conditions

Real-time congestion updates help route optimisation using predictive analytics systems to reroute vehicles around accidents or gridlocks before drivers are affected. Delivery companies like Uber Eats and FedEx use this data to respond within minutes when roads slow down.

Weather Alerts and Hazards

Rain, snow, fog, or extreme heat can add minutes or hours to last-mile deliveries. Predictive tools use weather feeds to automatically reschedule, reroute, or reassign orders before problems escalate.

Vehicle Telematics and GPS

Location tracking, engine diagnostics, and fuel levels help predict not just delays, but mechanical failures. If one van is falling behind or showing unusual patterns, the system can shift deliveries to another vehicle mid-route.

Order, Warehouse, and Inventory Data

A predictive system adjusts routes when orders are cancelled, new orders come in, or inventory shifts unexpectedly. This prevents wasted trips and maximizes load efficiency.

Real-world examples show just how powerful this data fusion can be. DHL uses route optimisation using predictive analytics to reduce delivery times by up to 25% by combining weather, traffic, and driver data. Walmart’s internal AI system pulls livestock and distribution updates to avoid sending empty trucks on delayed routes. These aren’t pilot tests, they’re daily operations at scale.

When all these inputs come together, AI for delivery route planning becomes a dynamic command centre. Every delivery vehicle becomes part of a smarter, self-adjusting network. The result of route optimisation using predictive analytics? Fewer bottlenecks, happier customers, and a delivery system for that’s always a step ahead.

To explore how your business can apply the same frameworks, check out our predictive route optimisation services tailored for logistics, retail, and on-demand platforms.

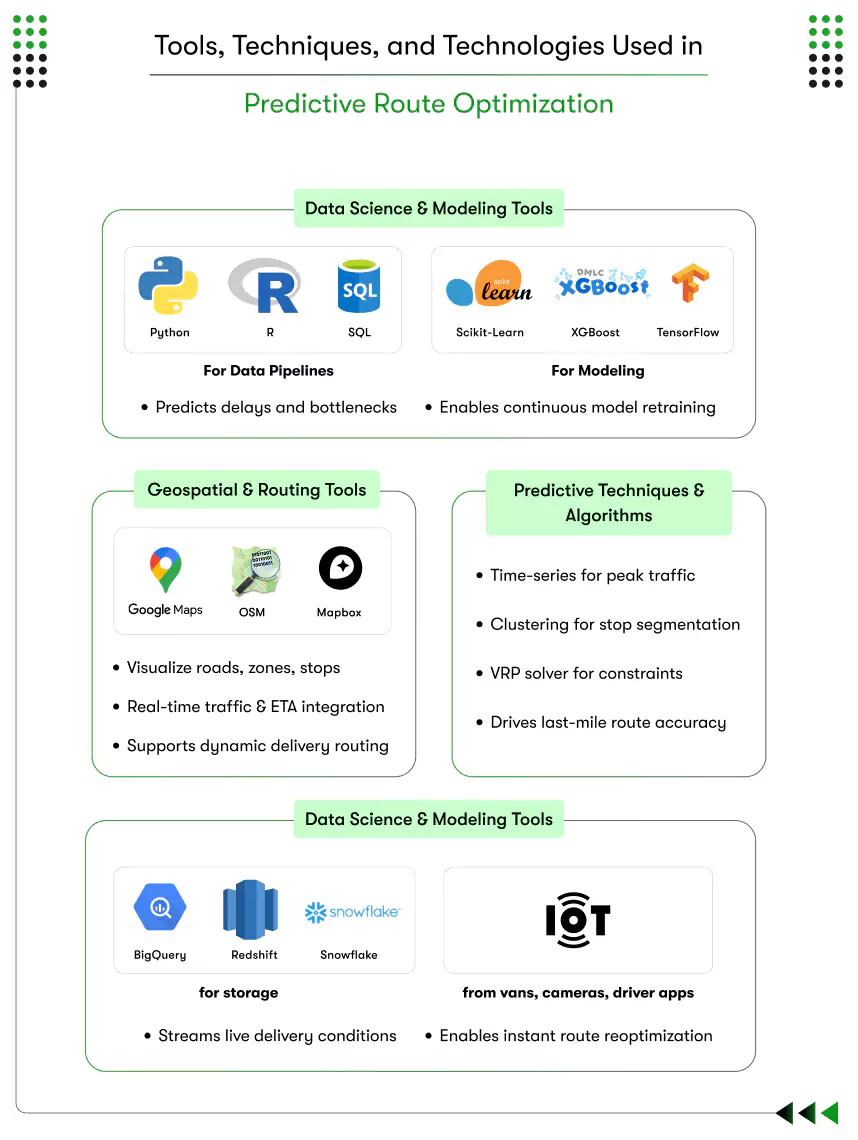

Advanced Tools, Techniques, and Technologies for Route Optimization Using Predictive Analytics

Route optimization using predictive analytics relies on a powerful mix of software tools, modeling techniques, and backend technologies. Each layer plays a role in building smarter, faster, and more adaptive delivery systems.

Let’s look at some of the tools, techniques, and technologies shaping route optimisation in delivery services:

Data Science and Modeling Tools

- Python, R, and SQL are used to process large logistics datasets, including location logs, delivery timestamps, and vehicle telemetry. These languages make it easier to build data pipelines that feed predictive models for route planning.

- Scikit-learn, XGBoost, and TensorFlow are machine learning libraries used to build and train models. These models forecast traffic delays, estimated delivery times, and route bottlenecks, making them vital to route optimization in delivery systems.

- These tools enable fast experimentation and continuous retraining, which is key for maintaining model accuracy in predictive analytics for route optimization workflows.

Geospatial and Routing Tools

- Google Maps API, OpenStreetMap, and Mapbox provide mapping layers and live traffic data. These tools allow systems to visualize delivery zones, road networks, and stop sequences in real-time.

- Delivery platforms use these services to generate precise routing paths, estimate travel time, and detect disruptions along the way. These geospatial engines ensure route optimization in delivery services reflects real-world road conditions.

- They also allow the integration of dynamic ETA calculations and distance-based route scoring, enhancing predictive analytics for delivery route optimization.

Predictive Techniques and Algorithms

- Time-series forecasting is used to predict variables like peak-hour traffic, recurring delays, and historical delivery trends. This helps delivery planners avoid congestion windows and reassign resources efficiently.

- Clustering algorithms group delivery stops based on location and delivery type. This is used to segment routes for different drivers or vehicle types, which improves last-mile delivery performance.

- Constraint-based optimization algorithms like the Vehicle Routing Problem (VRP) solver build delivery sequences that account for road closures, driver shift limits, and service windows. These enable truly data-driven predictive delivery optimization.

Infrastructure and Technology Stack

- Cloud data warehouses such as BigQuery, Redshift, or Snowflake store logistics data securely and make it accessible to analytics models in real time. This helps scale predictive operations across thousands of deliveries.

- IoT systems stream live input from delivery vans, traffic cameras, and driver mobile apps. These signals help the system monitor delays, location accuracy, and fuel efficiency in real time.

- The use of AI for delivery route planning depends on these technologies to reroute vehicles instantly and adjust schedules without human intervention.

These tools and technologies enable logistics teams to run highly intelligent routing systems with reduced fuel usage, faster ETAs, and fewer delivery failures.

Continuous learning loops powered by real delivery data improve prediction quality and ensure predictive analytics for delivery route optimization adapts to every new challenge on the road.

As a result, businesses achieve a strategic edge in on-time performance, route flexibility, and operational cost savings.

Route Optimization Using Predictive Analytics Challenges and How to Solve Them

Even with the growing adoption of route optimization using predictive analytics, many businesses still hesitate. The hesitation rarely stems from lack of value. Most resistance is driven by internal roadblocks that feel overwhelming at the start.

Fortunately, logistics leaders across industries are showing how to overcome hesitation using smart, phased strategies.

Common barriers include:

High implementation costs

Predictive systems often require upfront investment in data infrastructure, platform licensing, and team onboarding. These costs can feel risky, especially if returns are not immediate.

Successful teams mitigate investment concerns by launching pilot projects in a single delivery zone or vehicle cluster to demonstrate measurable gains before scaling further.

Dirty or siloed data

Many logistics firms work with inconsistent or disconnected datasets, which makes it difficult for the system to generate accurate route recommendations. Problems such as poor address quality, outdated fleet data, or missing traffic inputs can weaken model accuracy.

Logistics leaders address these issues through company-wide data cleansing efforts and API-based integrations that unify delivery, fleet, and inventory data into one ecosystem.

Workforce resistance and training gaps

When predictive models begin suggesting new routing strategies, some dispatchers and drivers may hesitate to trust the system. High-performing teams focus on blended decision-making, where human experience is used to guide and refine the model’s suggestions.

Proper training reframes the technology as a support tool that assists operations, rather than replacing human roles.

Legacy software limitations

Older route planning systems often lack the flexibility to support predictive features or real-time data integration. To modernize operations, companies adopt modular, API-friendly platforms that add predictive functionality on top of existing systems, without requiring a complete infrastructure overhaul.

Predictive Maintenance Integration

One overlooked but powerful solution is combining route optimization using predictive analytics with predictive maintenance for delivery fleets. If a vehicle shows early signs of engine issues or tire wear, predictive models can automatically reassign deliveries to another vehicle to avoid service delays.

This integration helps prevent disruptions caused by both mechanical failures and traffic-related delays, increasing reliability across every mile.

The journey toward predictive success does not require large, risky changes upfront. Instead, progress comes from small, strategic moves that build momentum through consistent operational wins.

What’s Next in Predictive Route Optimisation in 2025 and Beyond

The future of predictive route planning in logistics is no longer distant. It’s already unfolding, with businesses shifting from reactive delivery models to intelligent, self-optimizing fleets powered by real-time data and AI.

Here’s what the next wave of route optimisation in delivery services will look like:

AI-native delivery networks

Companies will design logistics systems from scratch with AI at the centre. These networks will adjust routes automatically based on order flow, traffic events, and supply chain changes without manual input.

Real-time orchestration across autonomous and electric fleets

As more electric and autonomous vehicles hit the road, routing models will need to factor in battery range, charging stations, and robotic movement limits. Predictive systems will make those calculations in real-time.

Eco-routing and compliance-focused optimisation

New tools will help delivery companies lower emissions while maintaining service levels. Predictive routing will offer not only the fastest route but also the greenest one.

Smarter demand planning integrated with routing.

AI won’t just optimize routes after orders are placed. It will predict where and when delivery demand will spike, allowing proactive vehicle deployment and load balancing. Companies using delivery demand with predictive analytics are already starting to align fleet planning with expected customer behaviour across time slots and locations.

Hybrid human-AI dispatch control towers

Dispatchers will work side-by-side with AI systems to monitor network performance, manage exceptions, and fine-tune predictive outputs, blending automation with operational expertise.

For logistics leaders, this means the clock is ticking, not to evaluate predictive technology but to scale it. Those who move early will optimize more than just routes. They’ll optimize cost, time, emissions, and trust.

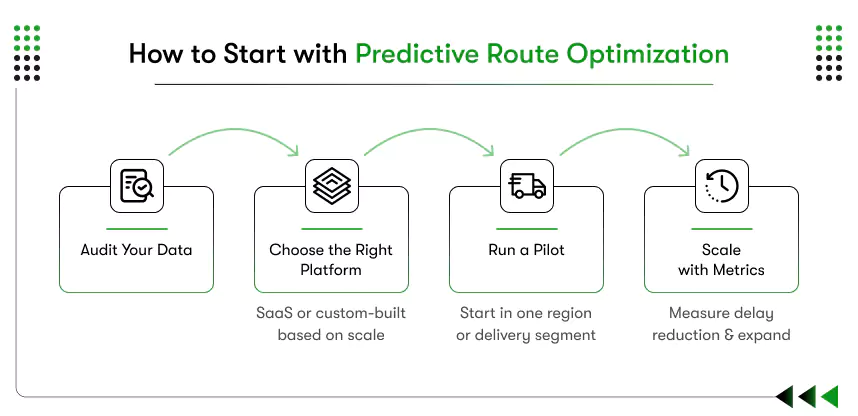

How to Start with Route Optimization Using Predictive Analytics for Delay Reduction

Getting started with route optimisation using predictive analytics doesn’t have to be complex. What matters is starting smart with a clear roadmap and the right foundation. Most successful companies begin by focusing on visibility and building from there.

Here’s how to move forward:

Start with real-time data visibility.

Before optimization comes observation. Track traffic patterns, delivery time variances, vehicle locations, and fleet status. These insights reveal where delays are happening and why.

Choose a platform or partner that fits your scale.

Whether managing 50 deliveries a day or 5,000, the tool you use should match your business size and operational model. Some companies go for off-the-shelf SaaS solutions, while others need custom predictive layers integrated into their ERP or TMS.

Make delay reduction a measurable KPI.

Set specific targets such as reducing average delivery time by 15% or cutting missed ETAs by 20%. Use predictive models to track improvements and validate the impact of each change.

Build around predictive strategy, not reactive fixes

Many companies still route based on static schedules. Switching to predictive analytics for delivery route optimisation means planning based on probability, not just past experience. It enables better resource use and faster customer service at scale.

Learn from the industries already doing it.

The logistics giants, food delivery leaders, and the retail supply chains are all leveraging Predictive Analytics in Delivery to drive speed, accuracy, and efficiency. Studying their approach can fast-track your own implementation and help avoid early missteps.

With the right data and tools, delay reduction is an achievable performance goal that delivers the real ROI across each and every mile and all orders.

For more information on improving delivery operations, Get our Delivery Predictive Analytics Consulting.

Final Thought on Route Optimization Using Predictive Analytics

Route optimization using predictive analytics gives delivery teams the power to stay ahead of delays, not just respond to them. Predictive analytics in route optimization enables accurate planning, real-time rerouting, and complete control over delivery operations.

Forward-thinking logistics teams are already seeing the shift. They’re using predictive systems to plan proactively, reroute in real time, and meet every delivery window without guesswork.

At Kody Technolab, we build intelligent routing systems that turn data into dependable results. From integrating delivery, fleet, and traffic data to deploying fully customized AI-based routing engines, our food delivery mobile app development expertise helps businesses reduce delays and take full control of their delivery operations.

If you’re ready to increase reliability, cut route inefficiencies, and lead your category with smarter logistics, our predictive delivery optimization solutions are built for you.

Take the next step toward data-driven delivery, and before your competitors do.

Contact Information

Contact Information