Are you one among the 62% of companies that reported human error as the root cause of inventory fulfillment issues?

And you want to be among the rising enterprises that automate 85% of their warehouse operations using technology and grow seamlessly?

If so, then read on.

Contrary to popular opinion, automating and optimizing operations aren’t the only offerings of tech-driven systems. They also help you improve inventory management, streamline order fulfillment, and enhance overall supply chain efficiency provided you have the right warehouse management system features.

But why do you need a Warehouse Management System – WMS?

As your business expands, efficiently managing warehouse operations becomes an agony. Orders get delayed due to manual processes, inventory inaccuracies lead to stock outs, and the workforce needs more efficient labor allocation.

If you want unstoppable growth, you must invest in developing a WMS or upgrading your warehouse management system features. Because a Warehouse Management System (WMS) with the right features can provide…

Real-time inventory visibility,

Automate order fulfillment,

Optimize warehouse layout,

Efficient labor management,

Data-driven insights,

And all this collectively improves customer satisfaction, reduces costs, and increases operational efficiency, among other achievements.

Therefore, a dynamic warehouse management system with the right features is crucial for thriving businesses.

How am I supposed to know what kind of features are suitable for my business? – you may wonder.

Read till the end; and you will get the answer!

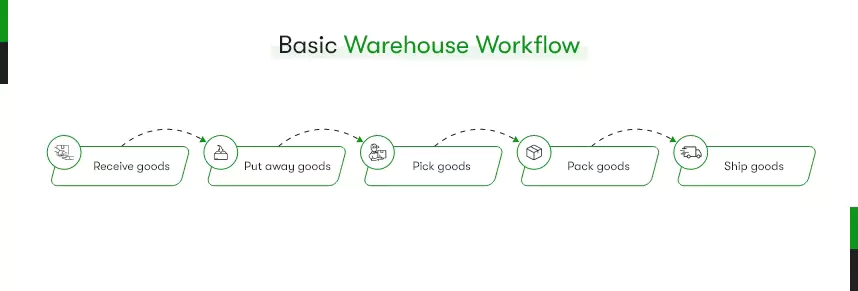

How does Warehouse Management function?

Before understanding the WMS requirements, it’s necessary to have a fundamental idea about how warehouse management software works. So, let us look into each step closely, from start to end.

Receive goods:

The WMS receives information about incoming goods from shipping documents, such as bills of lading. The WMS then scans the goods and updates its inventory records.

Put away goods:

The WMS uses inventory records to determine where to store the goods in the warehouse. The WMS then generates put-away instructions for warehouse workers.

Pick goods:

When a customer orders, the WMS retrieves the order information and generates a picking list for warehouse workers. The picking list tells the workers which goods to pick and where to find them in the warehouse.

Pack goods:

Once the goods have been picked, they are packed for shipping. The WMS generates packing instructions that tell the workers how to pack the goods and what materials to use.

Ship goods:

The WMS generates shipping labels for the goods. The shipping labels include the customer’s address and the shipping carrier’s information.

Do you want to know how WMS ensures each state’s success?

Here is how the Warehouse Management Software works under the hood!

Data Input:

The WMS receives data from various sources like ERP systems, barcode scanners, or manual inputs. This data includes information about inventory, orders, and warehouse configurations.

Inventory Management:

The system then tracks and manages inventory in real time. It updates inventory levels, locations, and statuses as goods are received, put away, moved, or picked within the warehouse. Consequently, the enterprise achieves accurate inventory visibility and prevents stockouts or overstocking.

Order Processing:

When customer orders are received, your Warehouse Management System processes them based on predefined rules. It generates pick lists or tasks for warehouse staff, specifying which items to pick and their locations. As a result, it streamlines the picking process, improving order accuracy and efficiency.

Warehouse Optimization:

The WMS optimizes warehouse layout and slotting. It suggests the most efficient storage locations based on item characteristics, demand patterns, and proximity to picking areas. That’s how you can reduce travel time, maximize storage capacity, and enhance overall productivity.

Labor Management:

The WMS warehouse management system optimizes your labor utilization by allocating tasks and tracking performance. It also provides guidance on task prioritization, picking routes, and work schedules, ensuring efficient use of workforce resources.

Integration and Communication:

It’s the best function of the Warehouse Management System. If you have transportation management systems (TMS), enterprise resource planning (ERP) systems, and e-commerce platforms, you can simply integrate them into WMS. This integration enables seamless data exchange and communication, ensuring end-to-end visibility and coordination across the supply chain.

Reporting and Analytics:

Another foremost Warehouse Management Software feature— Data collection throughout the warehouse processes and generates reports and analytics. So, you can set and monitor key performance indicators (KPIs) such as order fulfillment rates, inventory accuracy, and labor productivity. Furthermore, you can use this data-driven insight to identify areas for improvement, make informed decisions, and optimize warehouse operations.

Overall, the warehouse management system functions as a central hub to enhance efficiency and accuracy throughout the warehouse management process. It improves operations at each stage, from receiving goods to shipping them to customers. By automating warehouse management, a WMS also ensures smooth order processing and precise inventory control!

That being said, you are now qualified to get the warehouse management system requirements list. So, let’s forge ahead!

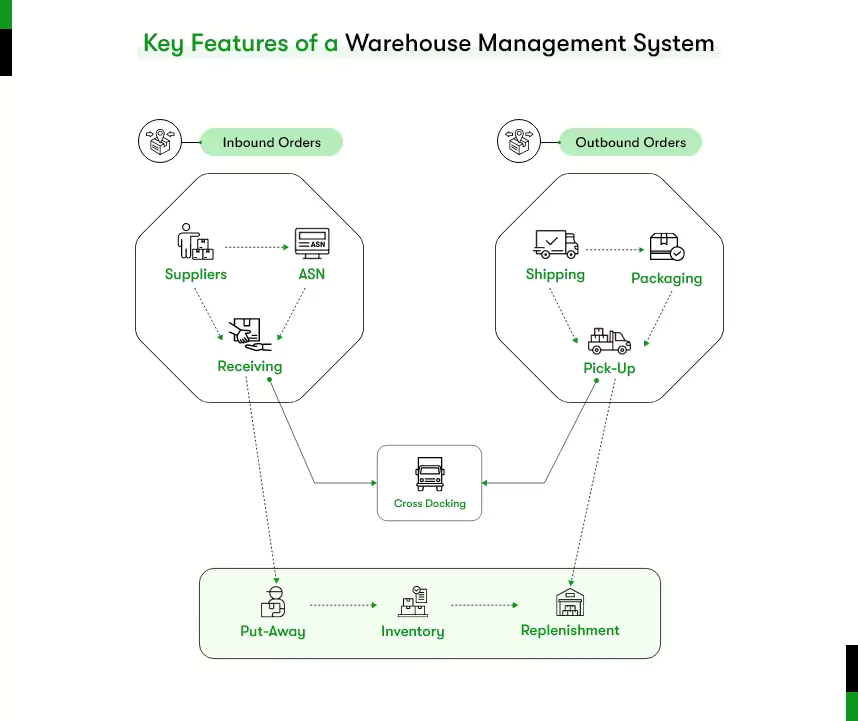

All you need to know about Warehouse Management Software Features

If you’re thinking of creating a custom Warehouse Management System (WMS) but need help deciding which features to include, no worries! You can look at this handy list of warehouse management software features.

We’ve categorized them based on their primary function stages. You’ll better understand the essential WMS requirements by referring to these categories.

Once these features are in place, you can streamline your warehouse operations, improve inventory control, enhance order accuracy, and boost overall operational efficiency.

However, remember to consider your business requirements and choose the perfect type of warehouse management system.

Receiving Goods

- Automated goods receiving process: Streamline and automate the process of acquiring goods, reducing manual effort and improving efficiency.

- Barcode scanning: Utilize barcode scanning technology to ensure accurate and efficient item identification during the receiving process.

- Real-time updates on received quantities and supplier information: Receive instant updates on stock quantities and essential supplier details to maintain accurate inventory records.

Inventory Management

- Real-time inventory visibility: Gain instant visibility into inventory levels and locations for better stock control and planning.

- Inventory tracking: Track and monitor inventory movements, ensuring accurate stock management and preventing stockouts.

- Batch and lot tracking: Implement batch and lot tracking capabilities to comply with regulations and enable traceability.

Order Processing

- Efficient order processing: Streamline the order processing workflow for quick and accurate order entry and handling.

- Order prioritization and routing: Prioritize and route orders based on customer requirements to ensure timely fulfillment.

- Automated order allocation: Automate the distribution of orders to picking and packing stations, optimizing workflow efficiency.

Picking and Packing

- Wave picking or batch picking: Group and optimize order picking tasks to improve efficiency and minimize travel time.

- Pick-to-light or pick-by-voice technology: Enable picking using technology-driven systems to enhance accuracy and speed.

- Packaging guidelines and instructions: Provide clear packaging guidelines and instructions to ensure proper packing of orders.

Shipping and Delivery

- Carrier integration: Seamlessly integrates with shipping carriers to generate shipping labels and track shipments.

- Shipping rate calculation: Calculate shipping rates in real-time to determine the most cost-effective shipping options.

- Order consolidation: Consolidate multiple orders into a single shipment to optimize shipping costs and improve efficiency.

Returns Management

- Streamlined returns processing: To enhance efficiency, automate the returns process, including return authorization and tracking.

- Return tracking and status updates: Track returns and provide status updates to customers for better service and communication.

- Disposition management: Effectively manage the disposition of returned products, including restocking or disposal.

Reporting and Analytics

- Comprehensive reports: Generate detailed reports on inventory levels, order fulfillment, and labor productivity for data-driven insights.

- Key performance indicators (KPIs) tracking: Monitor essential KPIs to evaluate performance, identify areas for improvement, and make informed decisions.

- Analytics and data visualization: Utilize advanced analytics and data visualization tools to gain valuable insights and identify trends.

To get an idea about the cost of developing a custom Warehouse Management System you should read: How much does Developing a Warehouse Management Software Cost?

Have you outlined your WMS requirements yet?

Warehouse Management Systems are just the beginning. You must integrate Robot solutions into your warehouse operations soon enough to compete in this fierce market.

Leveraging Warehouse Management Systems (WMS), you climb one step up in innovating your businesses. Whether you operate in eCommerce, manufacturing, pharmaceuticals, retail, or beyond, a WMS empowers you to boost efficiency, slash costs, and leave a lasting impression on your customers.

Invest in the custom WMS development services, leverage its key features, and drive business growth with an efficient and tailored solution. Stay ahead of the competition, exceed customer expectations, and transform your warehouse into a hub of productivity and success.

Contact Information

Contact Information